To maximize your oven's performance, you'll need to master seven essential heat flow elements. Start by enhancing airflow patterns with strategically placed fans and proper nozzle configurations. Position heat zones carefully to maintain perfect temperature gradients while using high-grade metals for superior heat conductivity. Install multi-layer insulation to prevent heat loss and manage humidity levels for consistent results. Implement smart temperature controls across multiple zones and guarantee ideal fan placement for uniform heat distribution. From industrial ovens to commercial units, these proven techniques will help you release your oven's full potential.

Designing Perfect Air Flow Patterns

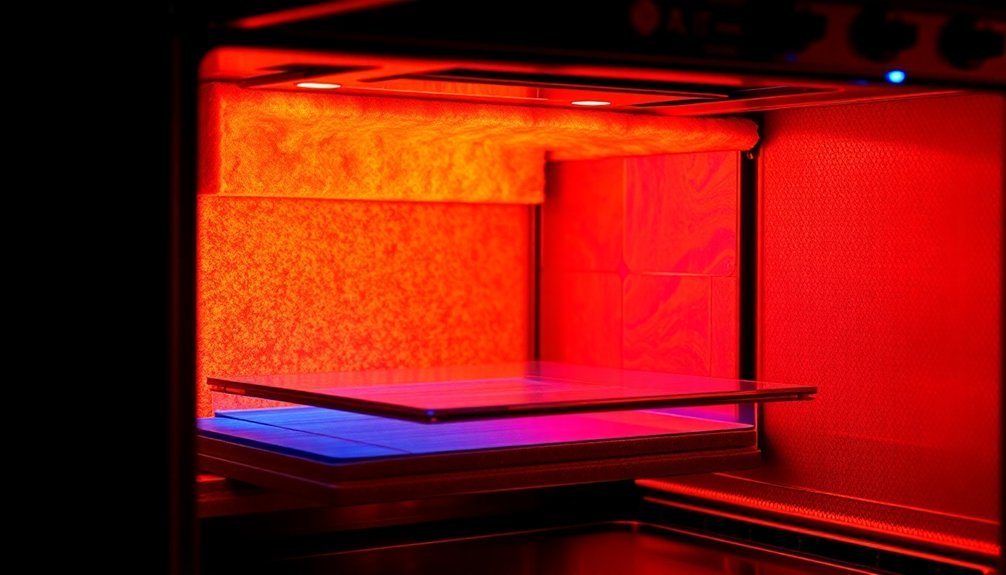

When designing an industrial oven, mastering airflow patterns is essential for achieving ideal performance.

You'll need to choose between four main configurations: horizontal/vertical for large parts on flatbed carts, vertical for hung products, full horizontal for shelved items, or combined patterns for large surface areas during heat treatment.

To maximize efficiency, you'll want to focus on key design elements.

Install oversized fans to increase CFM and maintain consistent airflow throughout the chamber.

Add floor radii along the oven walls to preserve high-velocity air movement. The collision of high and low velocity streams creates an oven breakpoint zone that effectively penetrates and cooks the product.

Design specialized trucks that minimize flow obstruction, and divide your oven into quadrants for precise control.

Don't forget to adjust nozzle openings in the plenum system to guarantee uniform air volume distribution, rather than focusing solely on air velocity.

Strategic Heat Zone Placement

You'll find that mastering heat zones starts with understanding the top-to-bottom distribution patterns in your pizza oven, where the dome temperature should reach about 1000°F while maintaining 750-850°F at the cooking surface.

To achieve ideal multi-zone temperature control, you're going to need strategic positioning of your heat source, whether it's wood embers or gas burners, along with regular monitoring using both infrared and traditional oven thermometers. Opening the chimney damper fully helps establish proper airflow for optimal heat distribution across zones.

Your heat loss prevention strategy should include proper insulation materials and careful placement of the oven away from temperature-sensitive appliances, while maintaining consistent cleaning practices to guarantee efficient heat distribution.

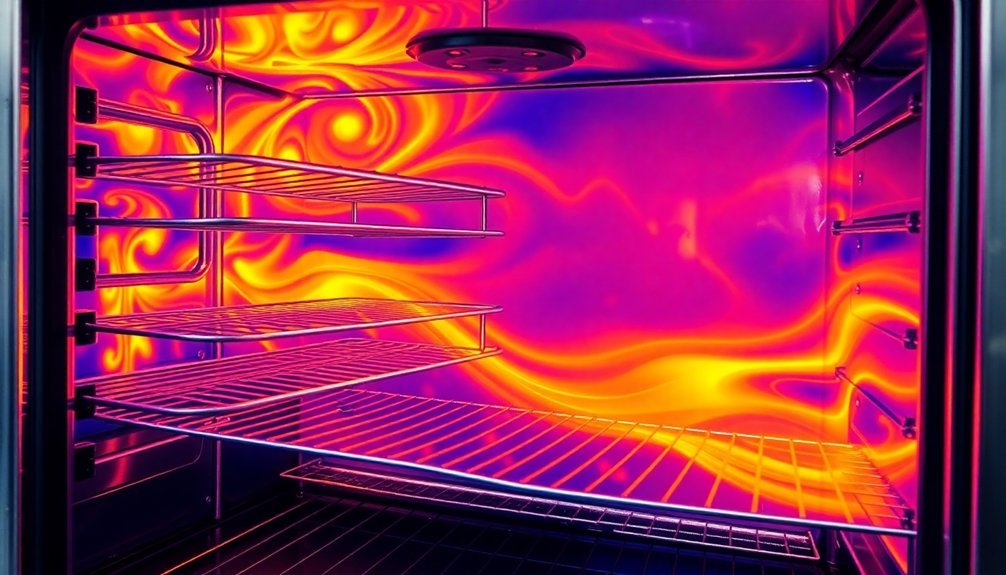

Top-to-Bottom Heat Distribution

Understanding your oven's heat distribution zones empowers you to achieve perfect results every time you bake.

Your top rack delivers intense direct heat, perfect for browning casseroles, broiling meats, or melting cheese to golden perfection.

The middle rack is your go-to spot for even heat distribution, making it ideal for cakes, cookies, and bread that need consistent temperatures. You'll get uniform rising and perfect crusts without burning.

Your bottom rack harnesses intense heat from below, creating crispy bases for pizzas and hearth-style breads. Making small 5% temperature adjustments can dramatically improve your baking results.

When you're baking directly on the deck, you can fine-tune the bottom stone's temperature by adjusting setpoints or the "Bottom Stone %" setting to prevent burning.

Remember to conduct test bakes to find your oven's sweet spots.

Multi-Zone Temperature Control

Multi-zone temperature control revolutionizes your baking precision by dividing the oven into distinct heating sections. You'll achieve ideal results through customized heating phases while maximizing energy efficiency and preventing common defects like solder bridging. Advanced airflow management systems ensure temperature uniformity throughout each heating zone for optimal soldering results.

To maintain peak performance, you'll need to focus on:

- Zone segregation maintenance through regular temperature audits and proper damper placement

- Smart control implementation that adjusts thermal power based on product flow

- Consistent calibration of temperature sensors and cleaning of the chamber to guarantee accurate heat distribution

Your heat zones' effectiveness depends on proper balance and maintenance. By implementing center-fed chevron burners and variable-speed convection systems, you'll assure balanced lateral heat distribution.

Plus, you can tailor temperature profiles, width, and length settings to match your specific product requirements and desired throughput.

Heat Loss Prevention Tactics

Strategic placement of heat zones works alongside robust insulation and airflow management to maximize oven efficiency.

You'll need to position your oven away from drafts, windows, and high-traffic areas that can disrupt temperature stability. Additionally, make certain it's not directly touching concrete floors, which can draw heat away.

To maintain peak heat zones, you'll want to focus on proper door management and rack placement.

Don't open the door unnecessarily during cooking, as this disrupts temperature consistency. When using multiple racks, arrange them to promote even air circulation.

You can improve heat retention by using high-quality insulation that exceeds the traditional one-inch-per-100°F rule.

Make sure your ductwork and fan systems direct airflow efficiently to prevent heat from escaping through exhaust stacks or bypassing your food entirely.

Maximizing Thermal Reflection Points

Effective thermal reflection points in an oven rely on three key dynamics: air stream collision, damper positioning, and breakpoint movement.

You'll achieve peak performance by understanding how high and low-velocity air streams create redirected horizontal flow across your products.

To maximize thermal reflection, you'll need to:

- Monitor damper rotation carefully – when both dampers are half-open, you'll find the breakpoint at the 6 o'clock position.

- Track breakpoint movement across both sides of the oven to prevent inconsistent cooking and yield issues.

- Test cross-belt uniformity using evenly spaced thermocouples to verify reflection effectiveness.

Your zone separation plays a vital role in maintaining these reflection points.

Managing Humidity For Better Performance

Proper humidity management in your oven can dramatically impact product quality, from crust development to internal texture.

You'll need to balance multiple factors to achieve ideal results. Higher humidity levels help maintain moisture content, allowing dough to expand further before the crust sets, while reducing direct heat transfer.

To control humidity effectively, you can use steam injection, purge systems, or air-atomizing nozzles.

Keep in mind that your oven load affects moisture levels – more products mean higher humidity and slightly lower temperatures.

For artisan breads, you'll want to maintain higher humidity levels through steam injection, while cookies and crackers often require less moisture to prevent case-hardening.

Don't forget to monitor your extraction systems and dampers, as they're essential for maintaining the right balance throughout the baking cycle.

Temperature Control Through Multiple Zones

While single-zone ovens can get the job done, multi-zone temperature control systems offer superior precision and flexibility for commercial baking operations.

You'll gain better control over your baking environment by managing up to 32 independent zones, each communicating through a centralized PLC and HMI interface.

Modern multi-zone systems deliver these critical advantages:

- Real-time temperature monitoring and adjustment across all zones through Ethernet connectivity and Modbus® integration

- Individual high-limit safety shutdown capabilities that prevent overheating while maintaining production in unaffected zones

- Quick component replacement and zone isolation features that minimize downtime when maintenance is needed

You can easily program and monitor your zones using proprietary software, ensuring consistent results while maintaining safety standards.

The system's redundancy protects your operation from complete shutdowns if a single component fails.

Optimal Fan Positioning Methods

Strategic fan positioning transforms your oven's performance by maximizing airflow efficiency and temperature consistency.

You'll achieve up to 50% increased airflow and 35% reduced cook times by selecting larger fans and positioning them to create unobstructed air paths.

Place your fans to support quadrant-based airflow control, ensuring every product receives equal air distribution.

You'll eliminate hot and cold spots while boosting capacity by 20%.

Install radius curves along oven walls and floors where air needs to make 90-degree turns, maintaining velocity and precise breakpoints.

Position your fans to operate at their best efficiency point (BEP) to reduce maintenance needs and extend equipment life.

Consider both horizontal and vertical airflow patterns when mapping out fan locations, and you'll improve product yields by up to 10% while maintaining consistent quality across all zones.

Heat Distribution Through Material Selection

Your oven's performance depends heavily on the thermal properties of its metal grades, with higher-grade stainless steel and aluminum offering superior heat conductivity and distribution.

You'll get the most efficiency by optimizing insulation layers through strategic placement of materials like fiberglass or mineral wool, which trap heat effectively while maintaining safe external temperatures.

You can further enhance heat distribution by selecting surfaces with specialized conductive coatings, which help eliminate cold spots and promote even cooking temperatures throughout the oven cavity.

Metal Grade Thermal Properties

The selection of metal grades plays a pivotal role in achieving ideal heat distribution within ovens.

You'll find that pure copper and aluminum offer superior thermal conductivity compared to steel or titanium, making them excellent choices for even heat distribution.

When you're selecting metals for your oven components, remember that material purity greatly impacts performance.

For ideal heat distribution, consider these critical thermal properties:

- Thermal conductivity rates – copper leads at 384.1 W·m−1·K−1, while aluminum follows at around 160 W·m−1·K−1

- Temperature stability – pure metals maintain consistent conductivity across varying temperatures

- Crystal structure impact – uniform structures promote better heat flow, especially in high-purity metals

You'll get the best results by matching metal grades to specific oven zones based on their thermal properties and operating temperatures.

Insulation Layer Optimization

Building upon proper metal selection, insulation layer design stands as another cornerstone of oven performance. You'll achieve ideal results by implementing fiber blanket insulation with its impressive temperature range up to 2800°F and low thermal conductivity.

| Material Type | Benefits | Key Specs |

|---|---|---|

| Fiber Blanket | Lightweight, Strong | Up to 2800°F |

| Formable Ceramic | Shock Resistant | Corrosion-proof |

| Board With Vestibule | Uniform Heating | Minimal Loss |

For maximum efficiency, you'll want to maintain a 50mm ideal thickness and incorporate multi-layer configurations with air gaps. Don't forget to reinforce corners with double-thickness material and use ceramic standoffs for 10mm base spacing. Your insulation strategy should include high-temperature silicone seals at joints and flexible thermal gaskets at edges. These measures will help you achieve the target thermal resistance of 1.25 m²K/W.

Heat-Conductive Surface Coatings

While designing an effective oven system, selecting appropriate heat-conductive surface coatings plays a vital role in enhancing thermal performance.

You'll want to take into account materials with high thermal conductivity like copper or aluminum, while factoring in their specific heat capacity and thermal expansion properties.

For maximum heat transfer efficiency in your oven, focus on these significant coating considerations:

- Apply ceramic coatings that create effective barriers against heat loss while maintaining ideal surface temperatures.

- Select coatings with high reflectivity and low thermal emittance to control heat absorption and distribution.

- Make sure your chosen coating can withstand extreme temperature fluctuations without losing adhesion.

You can apply these coatings using brushes, rollers, or airless sprayers, adding multiple layers when needed for enhanced insulation.

Frequently Asked Questions

How Often Should Industrial Oven Heating Elements Be Calibrated for Optimal Performance?

You'll need to calibrate your industrial oven heating elements every 6-18 months, depending on precision needs. High-precision operations require 6-month intervals, while less critical applications can extend to 18 months or longer.

What Safety Features Prevent Overheating if Temperature Sensors Malfunction?

You'll find multiple safety features protect against sensor malfunctions, including dual monitoring systems, backup thermostats, automatic shutdowns, and self-diagnostic functions. Your oven's redundant sensors provide overlapping protection against dangerous overheating situations.

Does the Type of Power Source Affect Heating Uniformity in Industrial Ovens?

Yes, your power source can impact heating uniformity. Electric heating provides precise control and even distribution, while gas heating may create hot spots but offers faster temperature changes and lower operating costs.

How Do Seasonal Temperature Changes Impact Industrial Oven Energy Consumption?

You'll notice higher energy consumption in winter due to greater heat loss. In summer, you'll use less energy for heating but may need more cooling power to maintain ideal temperatures and ventilation.

What Maintenance Schedule Ensures Consistent Air Pressure Levels in Circulation Systems?

You'll need to follow weekly vent cleaning, monthly seal checks, and quarterly gasket inspections. Don't skip your annual professional inspection to maintain proper air pressure throughout your oven's circulation system.

In Summary

You'll find your oven performing at its peak once you've implemented these seven heat flow principles. By optimizing airflow patterns, positioning heating elements strategically, and managing humidity levels, you're ensuring even cooking throughout. Don't forget that proper fan placement and material choices play essential roles too. Put these secrets into practice, and you'll transform your oven into a precision cooking machine.

Leave a Reply