You can reduce sauces naturally using several eco-friendly heat methods. Try a parabolic mirror setup with a black cast iron pan positioned at the focal point, or use solar dehydration with a collector box for concentrated flavors. Natural stone surfaces like granite offer excellent heat distribution, while wide, shallow pans optimize surface area for better reduction. Solar box cookers and glass dome techniques provide controlled environments for slow reduction. You'll also find success with sun-powered evaporation processes and reflector arrays for enhanced efficiency. Proper temperature control and consistent stirring are essential for all methods. Let's explore these sustainable cooking techniques in detail to transform your sauce-making process.

Direct Solar Pan Reduction

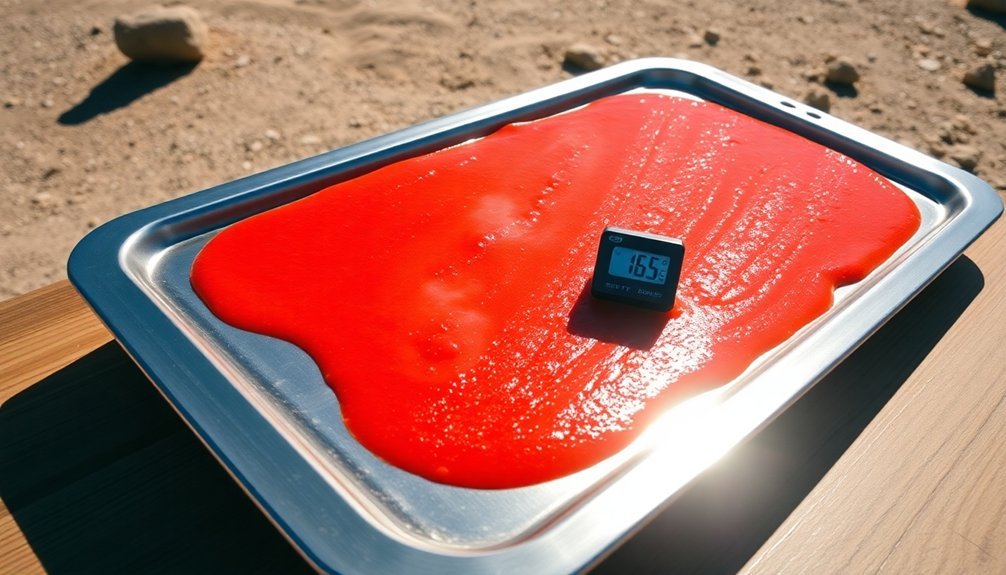

Anyone looking to reduce sauces through solar power should understand the significant limitations of direct sun exposure.

You'll find there's no documented method for successfully reducing sauces using direct sunlight, as the heat is too variable and uncontrolled for consistent results.

You can't rely on direct solar exposure because it doesn't provide the precise temperature control needed for proper sauce reduction. Proper reduction requires high sustained heat to achieve effective emulsification and thickening. The process is weather-dependent and slow, making it impractical for most cooking situations.

You'll also face food safety concerns when leaving sauces exposed to outdoor conditions.

If you're interested in natural heat reduction, you're better off using traditional stovetop methods with wide, shallow pans.

These proven techniques offer the control and consistency you need for successful sauce reduction.

Parabolic Mirror Sauce Cooking

You'll find that controlling sauce reduction with a parabolic mirror requires precise adjustments of your mirror's angle every 25-30 minutes to maintain consistent heat levels.

When setting up your reflective surface, position your black cast iron pan at the focal point, typically 17-18 inches from a 46-inch mirror, to achieve ideal heat concentration for sauce reduction. Consider adding salted butter first before introducing other sauce ingredients to establish a proper base for reduction.

Weather conditions can greatly impact your cooking process, so choose clear, sunny days with minimal wind to guarantee steady heat distribution and prevent unexpected temperature fluctuations.

Solar Heat Control Methods

While traditional sauce reduction methods rely on stovetop heat, parabolic mirror cooking offers an efficient solar-powered alternative. You'll need to maintain precise temperature control by positioning your cookware at the focal point and adjusting it as the sun moves. For darker sauces, you can use direct sunlight, while lighter sauces require indirect heating to prevent scorching. The process requires careful simmering and monitoring to achieve optimal sauce consistency.

| Heat Control Method | Temperature Range | Best For |

|---|---|---|

| Direct Focus | 50°-55°C | Dark Sauces |

| Indirect Heat | 45°-50°C | Light Sauces |

| Fresnel Lens | Variable | Slow Reduction |

| Heat Platform | 50°-55°C | Even Heating |

| Auxiliary Heat | As needed | Cloudy Days |

Don't forget to wear protective eyewear when working with parabolic mirrors, and regularly stir your sauces to guarantee even heating. You'll find this method especially effective when reducing seafood-based sauces like Alfredo.

Reflective Surface Setup Tips

Setting up a parabolic mirror for sauce reduction requires precise positioning and careful attention to detail. You'll need to position your mirror directly facing the sun, adjusting its angle to concentrate sunlight onto your cooking area.

Make certain your pot or pan sits perfectly at the focal point using a sturdy pot stand. As the sun moves across the sky, you'll need to reposition your setup periodically to maintain ideal heat concentration.

For the best results, use black cast iron cookware, as it absorbs sunlight more effectively than reflective surfaces like aluminum. If your pot isn't black, you can paint its exterior to improve heat absorption.

Always verify your cookware can handle the intense heat generated by the parabolic mirror's focused sunlight.

Weather Impact Considerations

Even though parabolic mirror cooking can achieve impressive temperatures, weather conditions greatly influence your sauce reduction success. While outdoor temperature isn't a major concern, wind poses the biggest challenge to maintaining consistent heat for your sauce.

You'll need to protect your setup from winds above 30 mph, as they can drastically cool your cooking vessel and prevent proper reduction. Position your equipment near natural windbreaks like walls or use portable screens to shield against gusts.

To minimize heat loss, make sure your pot has a well-fitted glass lid. Clear skies are ideal, but you can still reduce sauces on partly cloudy days if you've got direct sunlight.

Remember to adjust your mirror's position every 15-20 minutes to track the sun's movement and maintain peak heating temperatures.

Solar Box Slow Reduction

Although solar box cooking requires patience, it offers an effective method for reducing sauces without using traditional heat sources.

You'll need to minimize liquid content in your recipes and use tight-fitting lids to prevent excess condensation and heat loss. Keep your pots well-insulated to maintain consistent temperatures throughout the reduction process.

For the best results, you'll want to rotate your solar box cooker every 20 minutes to follow the sun's path – a Lazy Susan can make this task easier.

Rather than relying on time estimates, use a meat thermometer to monitor your sauce's temperature. Don't open the cooker frequently or stir unnecessarily, as this releases valuable heat.

Remember that weather conditions affect your reduction time; clear skies and minimal wind will help you achieve the best results.

Heat Retention Sauce Thickening

When you're choosing between copper and aluminum pans for sauce reduction, copper's superior heat conductivity makes it ideal for precise temperature control while aluminum offers a more budget-friendly option.

You'll notice that copper pans distribute heat more evenly across their surface area, leading to consistent sauce reduction and fewer hot spots.

Both materials will work for sauce reduction, but copper's excellent heat distribution properties make it worth the investment if you frequently make reduction sauces.

Copper Versus Aluminum Pans

Professional chefs and home cooks face a crucial decision when choosing between copper and aluminum pans for sauce reduction. You'll find copper's superior heat conductivity offers unmatched control and even heating, while aluminum presents a more budget-friendly alternative that's still effective for sauce work.

| Feature | Copper | Aluminum |

|---|---|---|

| Heat Control | Exceptional precision | Good responsiveness |

| Maintenance | Requires regular polishing | Low maintenance |

| Investment | Higher cost, lifetime durability | Affordable, replaceable |

While copper's thermal properties make it the gold standard for sauce reduction, you'll need to evaluate the maintenance requirements and higher cost. Aluminum's lighter weight and decent heat distribution make it a practical choice, though you might notice some hotspots with thinner pans. For professional results, contemplate investing in a thick copper pan, but don't rule out quality aluminum if you're budget-conscious.

Surface Area Heat Distribution

Beyond the choice of cookware material, understanding surface area's role in heat distribution can transform your sauce reduction technique. A larger surface area helps thin the boundary layer of still air around your pot, leading to more efficient heat transfer and better sauce reduction results.

- You'll get the best results with wide, shallow pots that maintain consistent temperatures throughout your sauce, unlike tall pots that create temperature variations between bottom and top.

- Your pot's base will always be hotter than its sides, so you'll want to stir frequently for even reduction.

- You'll need to balance surface area with practicality – larger pots transfer heat better but make boiling harder without a lid.

- You can achieve thermal efficiency above 45% by optimizing your pot's surface area, which speeds up the reduction process.

Solar Dehydration Method

Although traditional sauce reduction methods rely on stovetop heat, solar dehydration offers an eco-friendly alternative that concentrates flavors using the sun's natural energy.

You'll need a solar dehydrator with a collector box, clear glazing, and proper ventilation to effectively reduce your sauces.

Place your sauce in a single layer on the dehydrator's trays, ensuring good airflow throughout the system. You'll find the process works best on sunny days, and you'll want to cover the dehydrator at night or during rain.

While drying times vary, you can speed up the process by using optional solar-powered fans.

This method's benefits include zero electricity costs and better flavor retention.

If you're handy, you can build your own dehydrator using local materials for around $300, making it a cost-effective investment for sustainable cooking.

Thermal Mass Sauce Concentration

Thermal mass reduction harnesses stored heat energy to concentrate sauces without direct flame or electricity.

You'll find this method particularly effective when using heavy-bottomed pans or cast iron cookware that retain heat well. The residual heat continues to evaporate liquid while maintaining consistent temperatures, perfect for achieving the desired sauce consistency.

- Place your sauce in a wide, shallow pan with high thermal mass and pre-heat it thoroughly.

- Monitor the reduction process carefully, as the retained heat will continue working even after removing from heat.

- Add your aromatics early in the process to infuse flavors fully as the sauce concentrates.

- Adjust seasonings toward the end, since thermal mass reduction can intensify salt content.

Remember to check the sauce's thickness periodically, as thermal mass reduction tends to progress more slowly than direct heat methods.

Natural Stone Heat Transfer

When you're reducing sauces, natural stone's impressive heat retention properties can help maintain consistent temperatures throughout the cooking process.

You'll find that granite cooking surfaces, with their high thermal conductivity of up to 3.98 W/mK, distribute heat evenly and prevent hot spots that could scorch your sauce.

To get the most from your stone cooking surface, preheat it gradually and position it over low to medium heat, allowing the natural thermal mass to work in your favor.

Heat Retention Benefits

Despite their ancient origins, natural stones remain unmatched for their remarkable heat retention capabilities in modern cooking.

You'll find that lava stones and granite are particularly effective at maintaining consistent temperatures, which is essential when reducing sauces. Their high thermal conductivity guarantees even heat distribution throughout your cooking process.

- Natural volcanic lava stones hold maximum temperatures, letting you achieve perfect caramelization and seal in flavors.

- Granite's impressive k-value range of 1.73 to 3.98 W/mK makes it ideal for controlled sauce reduction.

- Lava rocks' porous structure creates superior heat distribution, perfect for slow, steady reduction.

- You can maintain consistent temperatures by using these stones as thermal masses in your cooking setup.

These properties make stone-based cooking methods particularly effective when you're looking to achieve professional-quality sauce reductions.

Stone Cooking Surface Tips

Understanding proper stone cooking surface techniques will dramatically improve your sauce reduction results.

You'll want to select granite that's 3-4cm thick, as it provides ideal heat transfer while maintaining durability. Before reducing sauces, season your stone with a light coating of oil, and let it reach proper temperature gradually.

Don't rely solely on surface temperature readings from an IR thermometer, as stone's internal heat differs from its surface reading.

When you're reducing sauces, you'll benefit from the stone's even heat distribution and natural non-stick properties once it's properly heated. Let marinades concentrate naturally on the heated surface for enhanced flavors.

After cooking, clean your stone by exposing it to high heat, but never shock it with cold water as this can cause cracking.

Glass Dome Reduction Technique

Research on natural sauce reduction methods doesn't support the effectiveness of a glass dome technique. Instead, professional kitchens rely on traditional reduction methods using wide, shallow pans over controlled heat to achieve the best results.

Your most effective reduction approach should focus on these proven techniques:

- Use a wide sauté pan to maximize the surface area for faster evaporation.

- Start with high heat to bring your liquid to a boil, then reduce to a steady simmer.

- Avoid adding salt until you've reached your desired consistency, as reduction concentrates flavors.

- Finish your sauce by swirling in cold butter over high heat for proper emulsification.

You'll get the best results by focusing on proper temperature control, continuous monitoring, and using appropriate cookware rather than experimenting with unproven glass dome methods.

Sun-Powered Evaporation Process

While traditional sauce reduction relies on stovetop heat, sun-powered evaporation offers a sustainable alternative that harnesses solar energy.

You'll need a dark-colored, layered vessel tilted at an angle to maximize sun exposure and natural circulation.

Set up your reduction system with an evaporator layer on top and a condenser layer below. The sun's heat will cause your sauce to circulate in swirling patterns, similar to ocean currents, which helps maintain even consistency.

You'll notice the liquid moving through the connecting tube between layers, ensuring continuous flow and preventing ingredient settlement.

This passive system doesn't require electricity and can process up to 5 liters per hour when scaled properly.

You'll achieve efficient reduction while preserving the sauce's flavors, as the solar method provides gentler, more controlled evaporation than traditional stovetop techniques.

Solar Reflector Array Method

Taking solar heat reduction to the next level, a solar reflector array harnesses concentrated sunlight through strategically positioned V-shaped cells.

You'll find these cells arranged at precise 22.5° angles with 0.5-inch gaps, creating a powerful system that captures energy through multiple reflections. The fractal pattern allows for up to 100,000 reflections, generating considerably more heat than traditional flat arrays.

- You can achieve 670% more efficiency compared to standard setups

- The V-shaped design maximizes energy capture through inward-facing cells

- You'll need less space to generate the same amount of heat

- It works with both artificial and natural sunlight

This method's high efficiency makes it perfect for reducing sauces, as you'll get consistent, intense heat while using less space than conventional solar setups.

Frequently Asked Questions

Can Reduction Sauces Be Stored and Reheated Without Losing Their Consistency?

Yes, you can store and reheat reduction sauces while maintaining consistency. Just cool them quickly, store in airtight containers, and reheat gently. If needed, you'll be able to adjust thickness during reheating.

How Do Weather Conditions Affect Natural Heat Reduction Timing?

You'll find humidity and temperature affect evaporation rates considerably. On humid days, reduction takes longer, while dry, warm weather speeds up the process. Wind can also impact how quickly moisture evaporates.

What Materials Are Safest for Long-Term Sun Exposure During Sauce Reduction?

You'll want to use non-reactive glass or ceramic containers, as they're safest for prolonged sun exposure. Avoid metal or plastic, which can leach chemicals. Shield yourself with zinc oxide sunscreen while monitoring.

Does Altitude Impact the Effectiveness of Natural Heat Reduction Methods?

Yes, altitude greatly affects your natural heat reduction methods. You'll notice slower evaporation rates at higher elevations due to lower air pressure and temperature. You'll need to extend exposure times for desired results.

Can Natural Reduction Methods Work Effectively With Non-Traditional Sauce Ingredients?

Yes, you'll find that non-traditional ingredients like fruit juices, coconut milk, or even kombucha can reduce effectively. Just guarantee you monitor temperatures carefully since different liquids have varying evaporation points and sugar contents.

In Summary

You'll find these natural heat reduction methods not only save energy but also enhance your sauces' flavors in unique ways. Whether you're using direct sunlight, parabolic mirrors, or heat-retaining stones, you've got sustainable options for achieving the perfect consistency. Don't hesitate to experiment with different techniques based on your climate and available resources – you're contributing to eco-friendly cooking while creating delicious results.

Leave a Reply