Your solar oven needs reliable monitoring tools to guarantee peak performance and safe cooking. Start with a digital temperature probe (-50°C to 300°C range) for accurate food and cavity readings. Add an infrared heat measurement tool for surface temperatures and a solar irradiance meter to track solar energy input. You'll want a thermal data logger to record cooking patterns, and environmental monitors for humidity and wind conditions. Don't forget a solar tracking system, performance testing devices, and safety instruments like food thermometers. A thorough monitoring setup will transform your solar cooking from guesswork into precision. Let's explore each tool's specific features and applications.

Digital Temperature Probes

Digital temperature probes routinely serve as essential monitoring tools for your solar oven, offering precise temperature readings from -50°C to 300°C with instant results. The probes deliver ultra-fast responses in just 0.5-3 seconds. You'll find these lightweight devices especially useful for monitoring various foods in your solar cooking setup, from meats to desserts, with high accuracy and reliability.

The probe's versatile features include adjustable temperature alarms that'll alert you when your food reaches the target temperature. You can easily switch between °C and °F displays, and the built-in countdown timer helps you track cooking duration.

At just 83.8g, you won't have trouble handling or storing this compact device.

When using the probe, you'll need to insert the 18cm cable properly into the thermometer side and place the 0.4cm probe accurately in your food for internal temperature readings.

You've got three mounting options: magnetic attachment, bracket installation, or suspension, making it adaptable to your solar oven setup.

Remember to use the ON/OFF button to preserve the AAA battery life, and regularly check both probe and battery condition. With proper care, your digital temperature probe should serve you reliably throughout its 2-year warranty period.

Infrared Heat Measurement Tools

You'll find infrared heat measurement tools invaluable for checking your solar oven's temperature without opening the lid, as they can detect heat from a safe distance of up to 50:1 ratio.

These tools let you spot temperature variations and heat patterns across your cooking chamber, helping you identify hot and cold spots that might affect cooking performance.

The tools feature a dual-laser design for pinpoint accuracy when targeting specific areas of your solar oven.

Your measurements will be quick and accurate with a 0.5-second response time, though you'll need to remember that shiny surfaces and glass can interfere with readings.

Temperature At A Distance

Accurately measuring your solar oven's temperature without opening the lid is possible with infrared thermometers. You'll get readings in just 0.5 seconds, with temperatures ranging from -50°C to 550°C. The dual-laser design guarantees you're targeting the right spot, while the backlit LCD display makes it easy to read measurements in any lighting condition. Regular monitoring helps achieve the ideal temperature range 300-400°F for effective solar cooking.

| Feature | Benefit | Limitation |

|---|---|---|

| Dual Laser | Precise targeting | Don't aim at eyes |

| Quick Response | 0.5s readings | Affected by steam |

| Wide Range | -50°C to 550°C | Can't read through glass |

| Adjustable Emissivity | Suits different surfaces | Needs direct line of sight |

| Distance Reading | No lid opening needed | Less accurate on reflective surfaces |

When using your infrared thermometer, you'll need to measure directly on food surfaces, as readings through glass won't work. For shiny surfaces, apply non-reflective tape or matte paint to get accurate measurements. The thermometer runs on a 9V battery that lasts about 12 hours, and you can use it in temperatures between 0°C and 50°C. Remember to keep the sensor clear of dust and steam for the best results.

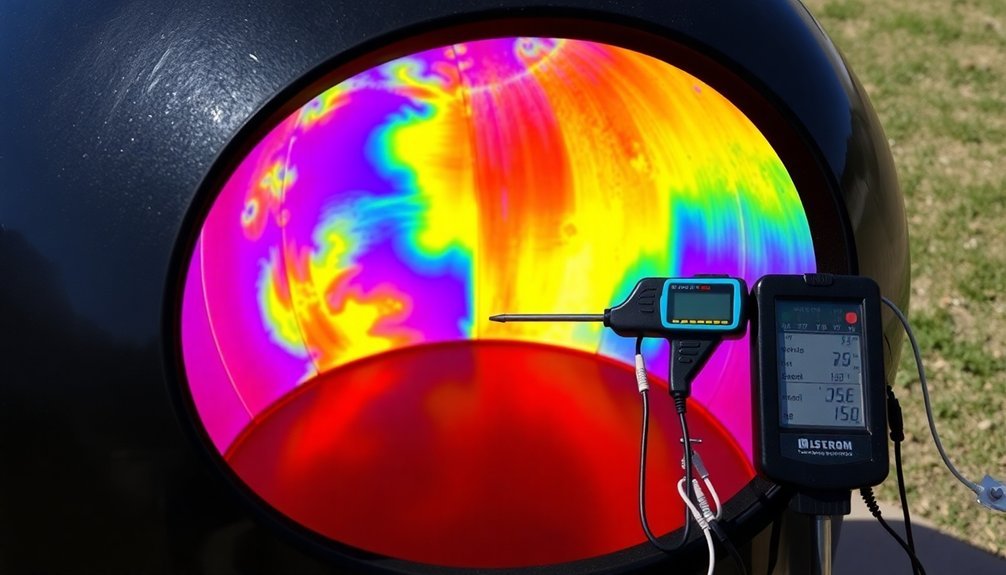

Heat Pattern Detection

Inside of your solar oven, heat patterns tell an important story about cooking efficiency. Using an infrared thermometer with dual-laser targeting, like the Solar Brother, you'll detect hot and cold spots that affect your cooking results. With a drop resistance of 3m, the 62 MAX+ ensures reliable measurements even in challenging outdoor cooking environments.

The precision of these tools becomes vital when you're trying to maintain consistent temperatures across your cooking surface.

For ideal heat pattern detection, you'll need to think about these critical features:

- Distance-to-spot ratio (higher ratios like 30:1 provide more precise measurements)

- Adjustable emissivity settings (0.1 to 1.0) for different surface materials

- Dual-laser targeting for accurate spot measurement

- Multiple measurement modes for continuous monitoring

When you're measuring heat patterns, remember that shiny surfaces can affect your readings. You might need to apply non-reflective tape or matte paint to get accurate measurements.

Steam and smoke can also interfere with your readings, so you'll want to minimize lid openings during testing.

Keep in mind that your thermometer's protective cover and proper storage (between -20°C and 50°C) will help maintain its accuracy over time.

With features like automatic shutdown and backlit displays, you can efficiently monitor your solar oven's performance in any lighting condition.

Solar Irradiance Meters

Solar irradiance meters let you measure the exact amount of solar radiation reaching your solar oven, helping you understand its ideal performance conditions.

You'll find both portable handheld models for spot checks and fixed monitoring systems that can track your oven's exposure to sunlight over extended periods.

Your choice between these options depends on whether you need quick occasional readings or want to analyze long-term performance patterns through continuous data collection. Quality meters like the SS200R model offer data logging capabilities that can record measurements at user-defined intervals over hours or days.

Accurate Radiation Intensity Measurement

Monitoring radiation intensity with precision is essential for optimizing your solar oven's performance. A solar irradiance meter will help you measure the exact amount of solar energy reaching your oven, with typical ranges from 100 to 1400 W/m² and resolution of 1 W/m².

You'll want to take measurements at regular 1-minute intervals to track intensity fluctuations throughout the cooking process.

When measuring radiation intensity, you'll need to take into account these critical factors:

- Angle of measurement should be within 35 degrees of direct sunlight

- Sensor must be properly leveled and free from obstructions

- Measurements should account for local shading conditions

- Regular calibration guarantees continued accuracy

Your readings will be most accurate when you follow proper measurement practices. Position your meter in the same plane as your solar oven's cooking surface, and guarantee it's not affected by nearby reflective surfaces.

The meter's LCD display should be easily readable in bright sunlight, allowing you to make quick adjustments to your oven's position.

Remember that accurate measurements help you determine the best cooking times and temperatures, ultimately leading to better results from your solar cooking endeavors.

Tracking Performance Over Time

Keeping tabs on your solar oven's performance requires reliable data collection over extended periods. You'll want to use monitoring tools that can log both irradiance and temperature data at regular intervals.

Modern data logging systems let you choose measurement frequencies between 1 to 60 minutes, storing up to 5000 datasets for thorough analysis of your oven's performance patterns.

To make tracking easier, you can wirelessly transmit data in real-time using Solarlink technology, which works up to 30 meters away from your monitoring device. You'll get simultaneous measurements of solar irradiance, ambient temperature, and your oven's temperature, all of which are vital for understanding performance efficiency.

The included software allows you to download this data to your PC for detailed analysis and certification reporting.

For maximum accuracy, you'll benefit from tools that include both a built-in inclinometer and compass function. These features help you optimize your oven's positioning by measuring the angle and orientation of your setup.

When combined with standard stagnation temperature monitoring, you'll have a complete picture of your solar oven's operational efficiency over time.

Portable Vs Fixed Models

Flexibility is a crucial factor when choosing between portable and fixed solar irradiance meters for your solar oven setup.

Portable models offer immediate readings and easy transport with carry cases, allowing you to test multiple locations quickly. You'll appreciate their compact design and high-contrast LCD screens that remain readable in bright sunlight.

Fixed models, while less mobile, excel at continuous monitoring and provide long-term data collection. They're ideal if you need consistent measurements from a single location and want to integrate readings with other monitoring systems. You'll benefit from their robust design and superior surge protection, though they require professional installation.

When selecting your monitoring solution, consider these key differences:

- Portable meters provide instant readings and location flexibility but need frequent calibration

- Fixed meters offer continuous data collection but have higher initial setup costs

- Portable options work well for spot-checking and troubleshooting various areas

- Fixed installations deliver reliable long-term data with minimal maintenance

Your choice should align with your monitoring needs – choose portable if you're regularly testing different spots or fixed if you need automated, continuous data collection from a permanent location.

Thermal Data Logging Systems

Accurate temperature tracking is essential for any serious solar oven user. To effectively monitor your solar oven's performance, you'll need a reliable thermal data logging system that can withstand high temperatures and provide detailed temperature profiles over time.

When selecting a data logging system, you'll want to focus on key components: a compact data logger, thermal barriers for protection, and Type K thermocouples for precise measurements. Systems like the Datapaq DP5 and ThermoVault offer robust solutions that include thermally insulated enclosures and high-temperature-resistant probe cables.

Your data logging setup should support a wide temperature range and minimize issues like false readings and data gaps. You'll need to guarantee proper installation and commissioning of the equipment, including correct labeling and positioning of probes.

Look for systems that are compatible with analysis software like MadgeTech 4, which allows you to visualize data and compute important performance indicators.

Don't confuse basic thermometers, like the Solar Brother Probe or standard solar cooking thermometers, with true data logging systems. While these simple tools can give you current temperature readings, they won't provide the continuous monitoring and data storage capabilities you need for detailed performance analysis.

Heat Distribution Analysis Equipment

Professional solar chefs rely on specialized equipment to analyze heat distribution patterns in their ovens. You'll need a combination of temperature measurement tools and solar radiation equipment to effectively monitor your solar oven's performance.

Thermocouples and infrared thermometers provide precise temperature readings, while data loggers help you track changes over time.

To measure solar radiation, you'll want to invest in essential monitoring tools:

- Solarimeters to determine radiation intensity

- Pyranometers for accurate irradiance readings

- Total solar radiation sensors to track energy absorption

- UV radiation sensors to measure ultraviolet components

For thorough analysis, you'll find thermal software invaluable. Programs like MadgeTech and Picolog help organize and interpret your data, while CFD software can simulate heat transfer processes.

When choosing heat absorption materials, consider that aluminum reaches higher peak temperatures but copper retains heat longer. You'll also need proper insulation materials and selective coatings to maximize efficiency. These materials work together with your monitoring equipment to create an optimized cooking environment.

Solar Tracking Alignment Tools

Through proper alignment tools, you'll maximize your solar oven's efficiency and cooking performance. Dual green laser technology provides precise positioning, helping you achieve the best energy collection throughout the day.

These alignment tools integrate with automated tracking systems that continuously adjust your oven's position to follow the sun's path.

You'll find these tools equipped with weather-resistant components, including laser systems, servo motors, and mounting hardware designed to withstand various environmental conditions. The tracking mechanisms use GPS and WiFi capabilities to guarantee autonomous operation, while solar-powered components make the system self-sustaining.

To set up your alignment tools, you'll need to carefully mount and calibrate the system. Start by securing the base and installing the tracking components, confirming proper balance and stability.

The dual laser beams will guide you in achieving precise angles, while the control systems allow for fine-tuning adjustments.

When installing, pay attention to the mounting hardware's security and the system's overall stability. You can customize the setup based on your specific needs, adjusting panel positions and tracking sensitivity to enhance your solar oven's performance in different seasons and weather conditions.

Environmental Condition Monitors

Monitoring environmental conditions is essential for maximizing your solar oven's performance. You'll need reliable temperature sensors that can measure between -40°C to 80°C with +/- 0.3°C accuracy. For precise readings, verify your temperature monitors have a 30-second thermal time constant and 0.1°C resolution.

Your environmental monitoring setup should include these critical components:

- Temperature sensors for ambient air and back-of-panel measurements

- Humidity monitors with 0-100% range and +/- 5% accuracy

- Solar irradiance sensors mounted on the panel's side

- Wind and barometric pressure monitors for detailed data

When installing humidity sensors, protect them from direct sunlight and precipitation while maintaining their ability to integrate with temperature monitors.

For solar tracking, use both global and plane-of-array irradiance sensors with secure mounting brackets.

Don't forget to monitor wind conditions using mini-aervane anemometers and track barometric pressure within 552-1084 hPa range. Your pressure monitors should maintain +/- 1.7 hPa accuracy with 1 hPa resolution.

Performance Testing Devices

Three essential devices form the foundation of solar oven performance testing: pyranometers, thermocouples, and anemometers. You'll use pyranometers to measure solar insolation, thermocouples to track temperature changes, and anemometers to monitor wind speed – all vital factors that affect your oven's performance.

For precise temperature monitoring, you'll want to invest in digital thermocouples or probe thermometers that can measure from -50°C to +300°C. These devices offer greater accuracy than analog alternatives and often come with helpful features like alarms and timers to track your cooking progress.

To properly evaluate your solar oven's performance, you'll need to follow standardized testing protocols like ASAE S580.1. You can use portable test stations equipped with control software to automate data collection and analysis.

Programs like Microsoft Excel, MadgeTech, or Picolog will help you process the data and calculate important metrics like cooking efficiency and the first figure of merit.

Solar Oven Safety Instruments

Building on our performance testing knowledge, safety instruments play an equally important role in solar oven operation. You'll need a reliable thermometer that can measure temperatures between 50°C and 300°C, with instant-read digital probes being particularly effective for monitoring both food and oven temperatures.

Your essential safety instruments should include:

- A durable stainless steel thermometer with dual °C/°F display

- Single-use gloves for proper food handling

- Sanitizing supplies for surfaces and utensils

- An oven-specific thermometer for constant temperature monitoring

When using these instruments, you'll want to maintain strict temperature controls. Pre-heat your oven to at least 140°F (60°C) before cooking, and make sure it stays above 180°F (82°C) throughout the cooking process.

If you're using a model with automatic sun tracking, you'll still need to monitor temperatures regularly to prevent food from entering the danger zone between 40°F and 140°F.

Keep your safety instruments clean and well-maintained, regularly sanitizing all surfaces that come in contact with food. Remember that proper placement of thermometer probes, whether in food or the oven cavity, is vital for accurate temperature readings and safe cooking results.

Frequently Asked Questions

How Often Should I Calibrate My Solar Oven Monitoring Tools?

You'll need to calibrate your monitoring tools annually for general use, but check manufacturer recommendations. If you're using them for critical measurements or notice inconsistent readings, consider calibrating every 6 months.

Can Monitoring Tools Affect the Cooking Performance of My Solar Oven?

Yes, your monitoring tools can impact cooking performance if they're not properly placed. They may affect air circulation and thermal dynamics, but you'll minimize interference by using non-invasive tools like infrared thermometers and proper insulation.

Which Monitoring Tools Work Best in Cloudy or Partially Shaded Conditions?

You'll get the most reliable readings in cloudy conditions using infrared thermometers and advanced solar monitoring systems. They'll work quickly and accurately even with limited sunlight, while vacuum tube monitors maintain consistent measurements.

Are Wireless Monitoring Systems More Reliable Than Wired Ones?

Wired monitoring systems are typically more reliable than wireless ones since they're less susceptible to interference. However, you'll find wireless systems offer greater flexibility and easier installation if signal strength is adequate.

What's the Average Lifespan of Solar Oven Monitoring Equipment?

You'll typically get 5-10 years from your solar oven monitoring equipment, though higher-end systems can last 15+ years. Regular maintenance and protection from harsh weather conditions will help extend their lifespan substantially.

In Summary

You'll get the most out of your solar oven by combining several monitoring tools that work together. Start with a basic digital probe thermometer and gradually add more sophisticated equipment like irradiance meters and data loggers as needed. Remember, proper monitoring isn't just about better cooking – it's about safety and efficiency too. Choose the tools that match your cooking style and technical comfort level.

Leave a Reply