Your oven's heat retention relies on several critical components working together. You'll find insulation layers, including ceramic fiber blankets and castable cladding, forming the first defense against heat loss. The interior's reflective surfaces bounce heat back toward your food, while strategic air flow systems guarantee even temperature distribution. Dense materials like cast iron and refractory concrete store thermal energy effectively, maintaining stable temperatures throughout baking. Proper sealing, using high-temperature gaskets, prevents heat from escaping around doors and openings. Understanding these heat-retention mechanisms can transform your baking from good to exceptional.

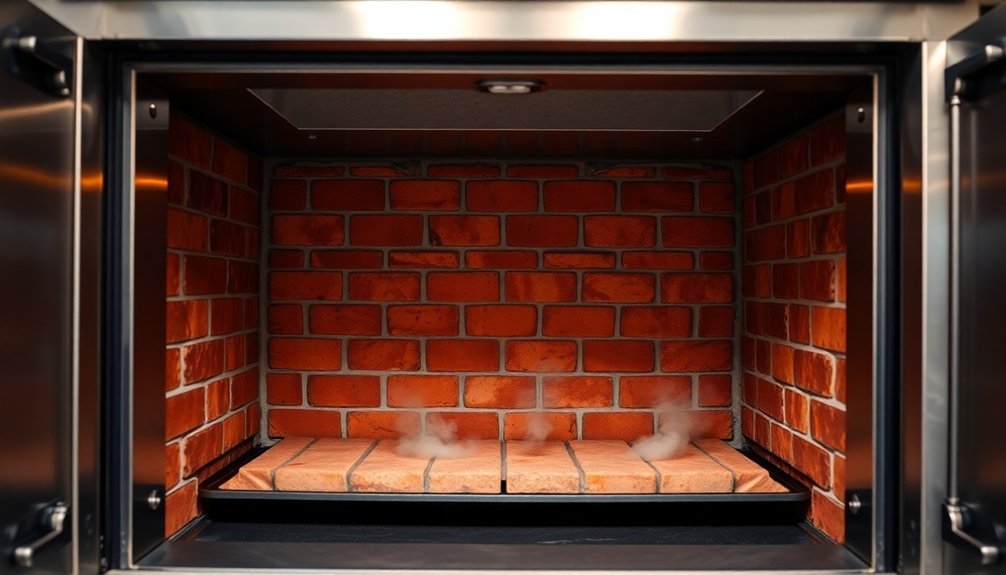

Insulation Layer Construction

When building an effective oven insulation system, you'll need to carefully layer different materials to maximize heat retention.

Start by placing a 3-inch ceramic fiber blanket directly on the oven dome, followed by up to 4 inches of castable cladding for enhanced insulation. A good balance between thickness and heat retention is vital for optimal baking performance. You can incorporate air pockets using empty bottles as an additional energy barrier between layers.

For the best results, you'll want to build your layers with denser materials at the base, working upward with lighter materials.

Cap the final layer with durable adobe or refractory bricks to protect the insulation underneath. Each layer should be about 2 inches thick, with a total insulation height of 6 inches or more.

Remember to guarantee complete coverage of all oven surfaces to prevent heat loss.

Surface Heat Distribution Mechanisms

Because effective baking relies on proper heat distribution, understanding the three primary heat transfer mechanisms is essential.

When you're baking, conduction occurs as heat moves directly from your pan to the food, while convection transfers heat through the circulating hot air. Radiation delivers heat through electromagnetic waves from the oven's walls and heating elements. Adding specialized devices like preheated pizza stones can enhance heat retention and distribution during baking.

You'll get the best results by managing these mechanisms effectively. Position your rack in the center for balanced heating, and consider using a convection setting if your oven has one – it'll speed up baking and provide more even results.

Remember that your pan choice matters too; darker pans conduct heat faster than lighter ones. If you notice uneven browning, rotating your pan during baking can help compensate for your oven's hot spots.

Reflective Material Positioning

Reflective materials serve as essential components in maximizing your oven's heat retention capabilities. You'll want to position these materials strategically by placing them at specific angles that direct sunlight onto your cooking surface. For ideal results, line your oven's interior walls with reflective surfaces while ensuring they align perfectly with any transparent openings. The use of smooth reflective surfaces significantly enhances the efficiency of light ray reflection toward the food being cooked.

| Position | Purpose | Impact |

|---|---|---|

| Side Walls | Multi-directional reflection | Thorough heat capture |

| Back Panel | Primary light redirection | Focused energy concentration |

| Interior Base | Heat absorption support | Enhanced temperature retention |

Air Flow Control Systems

Modern air flow control systems transform conventional ovens into precision cooking environments through advanced circulation technology.

You'll find ceiling-mounted axial fans and digital sensor arrays working together to eliminate hot and cold spots while maintaining consistent temperatures throughout the cavity. Continuous air movement ensures optimal heat transfer and uniform baking results across all shelves.

These systems integrate with rotating racks and steam injection to maximize heat distribution and retention.

- Precision Airflow Technology guarantees uniform heating from top to bottom, even when doors are left open, while supporting multi-rack batch cooking.

- Advanced velocity monitoring uses sensor arrays to profile airflow patterns, allowing real-time adjustments for ideal baking conditions.

- Patented systems like Total Flow Control™ let you customize breakpoint airflow locations and duration, increasing product yields by up to 10%.

The combination of convection fans and sophisticated airflow management creates an environment where your baked goods achieve consistent texture, color, and quality.

Thermal Mass Storage Components

In your ideal oven design, you'll want to incorporate dense materials like cast iron and refractory concrete as core thermal storage components.

Your heat retention surfaces should include a dual-slab system with an insulating sand layer that protects the support structure while maintaining consistent temperatures.

The strategic placement of these thermal mass materials creates distinct distribution zones that help your oven maintain stable temperatures, even when you're opening the door or loading food.

Core Construction Materials

Heat-retaining materials form the backbone of effective oven construction, with several key components working together to create ideal thermal mass storage.

You'll find refractory castable and concrete at the heart of many modern ovens, offering exceptional heat retention while maintaining structural integrity. Silica sand and firebricks complement these materials, creating a balanced system that stores and distributes heat efficiently.

- Soapstone stands out as a premium option, capable of retaining heat for up to 13 hours after your fire goes out.

- A dual slab system incorporating concrete and sand layers creates an excellent heat-retaining structure.

- Layering different materials, like combining concrete with firebricks, maximizes both heat retention and distribution.

These core materials work through conduction and radiation, ensuring your oven maintains consistent temperatures throughout the baking process.

Heat Retention Surfaces

Building upon the core materials discussed, thermal mass storage components serve as the powerhouse of your oven's heat retention system.

Dense materials like cast iron, ceramic stones, and bricks work as heat batteries, storing and releasing thermal energy gradually to maintain steady temperatures.

You'll find these components strategically placed near heat sources to maximize efficiency.

A dual-slab system with silica sand can protect your oven's support structure while ensuring consistent floor temperatures.

When you're using thermal mass materials, they should directly contact your cooking surface to promote effective heat conduction.

Thermal Distribution Zones

Modern ovens achieve remarkable temperature control through strategically placed thermal distribution zones.

You'll find multiple independent zones equipped with dedicated convection fans and exhaust systems, allowing precise management of temperature, humidity, and air volume throughout the baking process.

These zones work in tandem with high-density materials like refractory concrete and cast iron to maintain stable temperatures and promote efficient heat transfer.

- Strategic placement of thermal mass components creates a heat reservoir that quickly replenishes lost heat during baking.

- Independent zone control enables you to customize temperature settings for different types of baked goods.

- Advanced sensor technology monitors and maintains distinct temperature zones, reducing energy consumption by up to 20%.

The combination of thermal mass and zonal control guarantees consistent heat distribution while minimizing the need for frequent temperature adjustments during baking cycles.

Heat Seal Enhancement Methods

In modern ovens, you'll find that proper door gasket material selection is essential for maintaining consistent internal temperatures and preventing heat loss.

Your oven's effectiveness largely depends on carefully chosen silicone rubber compounds that can withstand temperatures up to 400°F while providing excellent steam resistance and tear strength.

Strategic cavity insulation layers work alongside these gaskets to create multiple thermal barriers, greatly reducing heat escape and improving your oven's overall energy efficiency.

Door Gasket Material Selection

Selecting the right door gasket material proves essential for maintaining perfect heat retention in ovens.

You'll find silicone rubber gaskets offer excellent temperature control from -67°F to 500°F, while fiberglass and ceramic options provide superior durability for high-heat applications.

When you're looking for custom-fit solutions, high-temperature rubber compounds can be molded to your specific needs.

- Silicone rubber gaskets feature low compression set and high tear strength, making them perfect for both home and commercial ovens.

- Fiberglass and ceramic materials can be enhanced with vermiculite coating to withstand temperatures up to 1100°C.

- High-temperature compounds with adhesive backing facilitate easy installation and reliable sealing across various oven models.

These materials can be further enhanced through specialized coatings and design features to prevent heat loss and maintain excellent baking conditions.

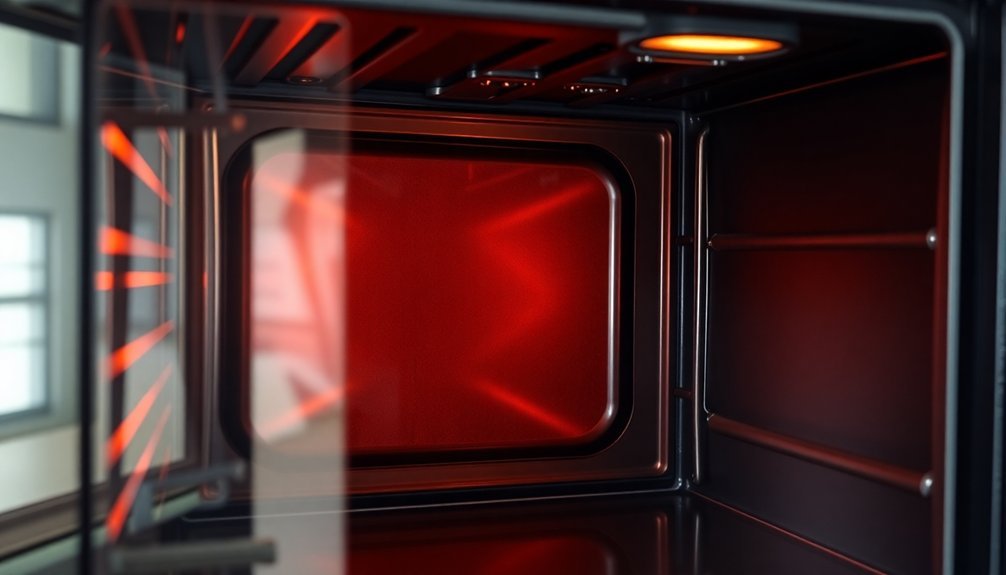

Strategic Cavity Insulation Layers

Strategic cavity insulation relies on a three-layer system that maximizes heat retention in modern ovens.

You'll find two distinct fiber layers – made of either glass wool or rock wool – working alongside a metallic sheet layer. The first fiber layer sits directly against the cavity wall, while the second layer forms the outer barrier.

Between these layers, you'll notice an aluminum foil sheet positioned less than 1cm from the wall. This metallic layer reflects thermal radiation effectively, while the fiber layers prevent heat conduction.

The first layer's density of 20-60 kg/m³ helps reduce heat transfer to the metallic sheet, and the second layer captures any escaping radiation.

This system's flexibility guarantees tight coverage, requiring minimal space while delivering peak insulation through its combined reflective and conductive properties.

Frequently Asked Questions

How Does Altitude Affect Baking Temperatures and Heat Retention in Ovens?

You'll need higher temperatures at altitude since air pressure's lower, causing faster evaporation. Your oven's heat retention stays similar, but you'll want to adjust baking times and temperatures to prevent dryness.

Can Electromagnetic Interference From Nearby Appliances Impact Oven Temperature Accuracy?

You don't need to worry about electromagnetic interference affecting your oven's temperature accuracy. Modern ovens are well-shielded, and their heating elements and thermostats operate independently of external electromagnetic fields from nearby appliances.

Does the Color of Bakeware Affect How Heat Is Distributed?

Yes, your bakeware's color markedly impacts heat distribution. Dark pans absorb and radiate more heat, requiring lower temperatures, while lighter pans provide more even baking. You'll need to adjust temperatures accordingly for best results.

How Do Power Fluctuations Influence an Oven's Ability to Maintain Heat?

Power fluctuations affect your oven's temperature stability through thermostat cycling. You'll notice temperatures can swing 8-10°C above or below your set point as the heating elements turn on and off to compensate.

What Role Does Oven Door Glass Thickness Play in Heat Retention?

Your oven's glass thickness directly impacts heat retention. Thicker glass panels (4-5mm) create better insulation and maintain stable temperatures. When paired with sealed air gaps, you'll experience improved heat retention during baking.

In Summary

You'll get the best heat retention from your oven when all components work together. The insulation layer traps heat effectively while the reflective surfaces bounce it back into the cavity. Your oven's thermal mass stores and releases heat steadily, and proper door seals prevent heat escape. Remember that efficient airflow distribution and even surface heating are essential for maintaining those maximum temperatures while baking.

Leave a Reply