The most effective insulation materials for your solar cooker include mineral wool, which withstands temperatures above 1,000°C, and reflective polystyrene that reflects 97% of radiant heat. You'll get excellent performance from recycled cellulose, offering high R-values while being eco-friendly. Fiberglass provides reliable thermal protection with R-values up to 3.8 per inch, while polyurethane offers 700% better insulation than traditional materials. Consider natural wool and wood fiber for sustainable options, and don't forget aluminum foil barriers for enhanced heat retention. Each material's unique properties can transform your solar cooking experience when you understand their full potential.

Mineral Wool Performance

When considering insulation for your solar cooking equipment, mineral wool stands out as a top performer across multiple criteria.

You'll benefit from its remarkably low thermal conductivity (0.0031-0.0045 W/mK), which prevents heat loss through your cooking equipment's walls and maximizes energy efficiency.

What makes mineral wool particularly suitable for solar cooking is its ability to withstand temperatures above 1,000°C while maintaining dimensional stability. The material provides enhanced fire protection that exceeds standard safety requirements.

You won't need to worry about degradation or performance loss, as it's highly resistant to moisture, chemicals, and corrosion.

Plus, you'll find it's lightweight and easy to work with – you can cut it precisely with a serrated blade for a perfect fit in your solar cooker.

These properties guarantee your cooking equipment maintains consistent performance while keeping energy costs low.

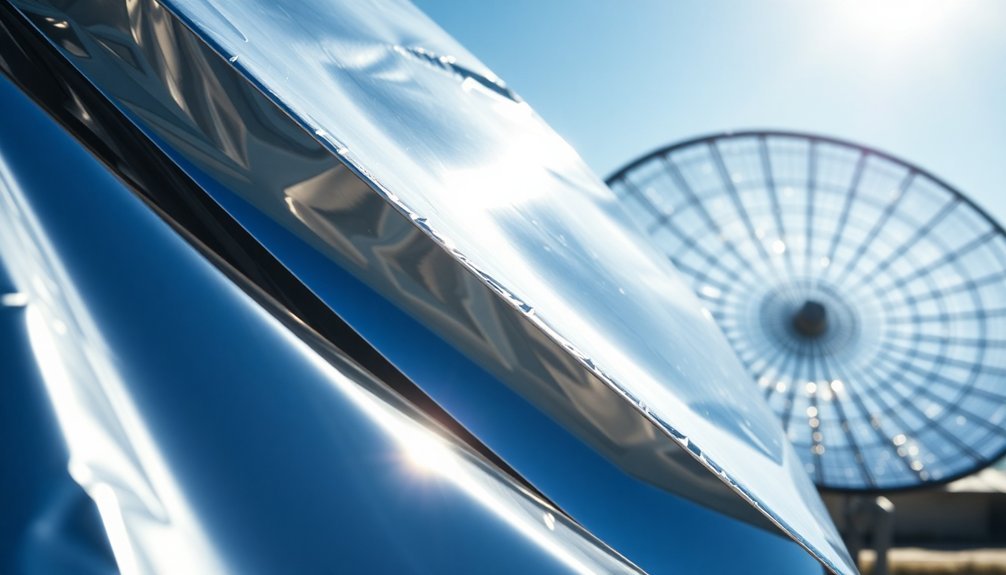

Reflective Polystyrene Applications

You'll find reflective polystyrene particularly effective for attic heat shield installations, where its 97% radiant heat reflection capability creates a powerful thermal barrier against intense sun exposure.

The long polymer chains of polystyrene provide exceptional durability and insulating performance in these applications.

Your building's exterior can benefit from sunscreen panels made with this material, which help reduce HVAC loads while maintaining dimensional stability in varying temperatures.

The combination of aluminum facers and polystyrene core makes these applications ideal for sun-exposed areas, offering both moisture resistance and superior thermal performance.

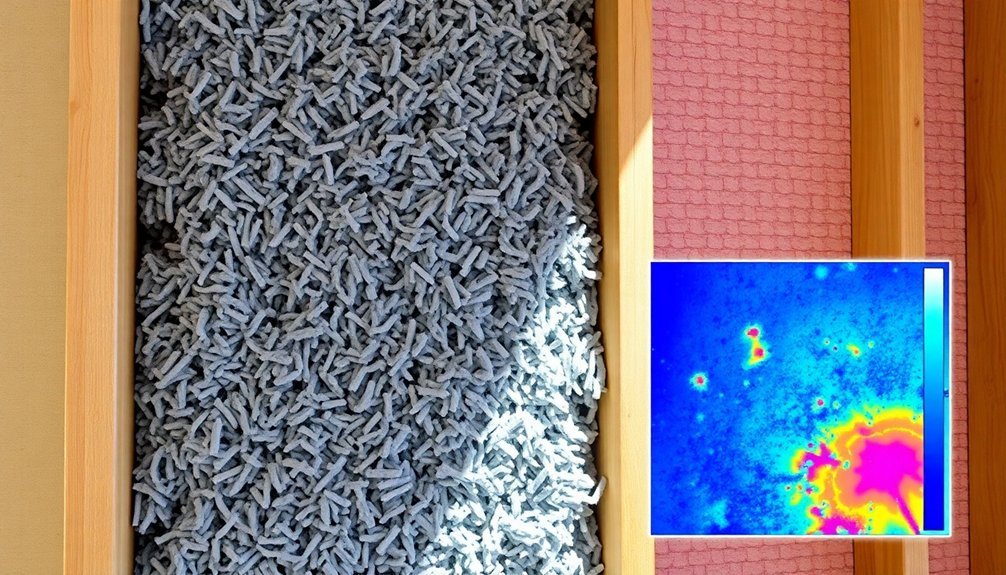

Attic Heat Shield Installation

Installing a radiant barrier in your attic requires careful planning and proper placement to maximize its heat-blocking potential.

You'll want to mount the reflective aluminum foil material on the underside of your roof deck or along the top chord of roof trusses, leaving gaps at the soffit and ridge for ventilation.

Don't install sheet barriers directly on top of attic floor insulation, as dust accumulation will reduce effectiveness.

If you're using foil-faced bubble products or "chips," you can place these on the attic floor.

You'll need a partner for safe installation – be careful not to compress existing insulation or risk falling through the ceiling. Using plywood or 1×12 across truss members will provide stable support during installation.

While small tears won't greatly impact performance, maintaining a clean reflective surface is vital.

When properly installed, you can expect to cut your cooling costs by 8-12% annually.

Building Exterior Sunscreen Panels

Many homeowners achieve superior thermal protection by incorporating reflective polystyrene panels into their exterior sunscreens. You'll find that these panels, featuring metalized facers, can greatly boost your home's R-value when properly installed with a dead air space.

For ideal performance, you'll want to position the reflective facers toward your home's interior. The panels are lightweight and rigid, making them easy to install between trusses or on flat surfaces. You can pre-cut them to fit specific spaces, and they're compatible with various roof membranes and waterproofing materials. Similar to the benefits of Phifer SunScreen, these panels provide excellent daytime privacy protection while maintaining clear visibility.

When you combine these panels with other insulation materials, you'll maximize energy savings through enhanced heat reflection and reduced air infiltration. The panels also help maintain steady temperatures, protecting your building from freeze-thaw cycles and weather-related damage.

Recycled Cellulose Benefits

Recycled cellulose stands out as an eco-friendly insulation powerhouse, offering both environmental and practical benefits.

You'll find that it's made from about 85% recycled materials, primarily paper that would otherwise end up in landfills. This sustainable choice helps reduce deforestation while emitting fewer greenhouse gases during manufacturing.

You'll appreciate how cellulose excels at thermal performance, keeping your sun chef space warm in winter and cool in summer.

It's got a higher R-value per inch than many fiberglass options, and it'll effectively seal those tiny gaps in your building.

You won't need to worry about pests either, as its borate content naturally deters them. Plus, you're getting excellent sound reduction benefits, and once it's installed, it'll last as long as your structure does.

Fiberglass Heat Retention Solutions

When you're choosing fiberglass insulation for your kitchen, you'll find R-values between 2.9 and 3.8 per inch, with higher ratings delivering superior heat retention for your cooking space.

You can maximize your investment by following proper installation protocols, including using safety equipment and ensuring complete coverage of air gaps that could compromise performance.

The initial costs of professional installation and higher-grade materials will pay off through reduced energy bills, as upgrading from R-19 to R-38 insulation delivers substantial annual savings in temperature-controlled environments.

Heat Protection Performance Ratings

Understanding fiberglass insulation's heat protection ratings starts with its impressive R-value range of 2.9 to 3.8 per inch. You'll find these values increase when you layer multiple sheets, as R-values are additive. This makes fiberglass an excellent choice for your sun chef's thermal protection needs.

| Performance Metric | Rating | Impact |

|---|---|---|

| Heat Retention | High | Less energy loss |

| Thermal Conductivity | Low | Better insulation |

| Fire Resistance | Excellent | Added safety |

| Temperature Stability | Good | Consistent performance |

When you're evaluating insulation for your sun chef, consider that fiberglass's thermal performance can vary with temperature and moisture levels. While thermal bridging through structural elements can affect overall effectiveness, you can combine fiberglass with insulating sheathing to enhance its performance and achieve ideal heat protection.

Installation Best Practices Guide

Having explored fiberglass insulation's performance ratings, let's focus on proper installation techniques that maximize its heat retention capabilities.

You'll need to measure your stud cavities and add 1/2" to guarantee a snug fit. When cutting the insulation, wear protective gear and use a utility knife to make precise cuts around obstacles.

For electrical wires and plumbing, split the batts and tuck them around these obstructions. Don't compress the insulation too much – you'll reduce its effectiveness by 50%.

Seal all gaps properly: use caulk for spaces under 1/4", spray foam for gaps up to 3/4", and stuff larger openings with insulation scraps.

Cost-Benefit Analysis Breakdown

To make an informed decision about fiberglass insulation, you'll need to weigh its impressive benefits against its initial costs. While it's one of the most affordable insulation materials available, its value extends far beyond the initial purchase price.

The long-term financial advantages of fiberglass insulation include:

- Reduced monthly utility bills through better temperature regulation

- Extended HVAC system lifespan due to decreased workload

- Minimal maintenance costs thanks to its moisture resistance

- Quick return on investment through energy savings

You'll find that fiberglass's durability and performance make it a cost-effective choice for your operation. Its high R-values of 2.9 to 3.8 per inch guarantee ideal thermal performance, while its composition of recycled materials helps reduce your environmental impact.

When properly installed with safety precautions, it's a reliable investment that'll serve your facility for years.

Polyurethane Thermal Efficiency

Because polyurethane delivers exceptional thermal insulation, it stands out as a top choice for Sun Chef applications. You'll find it provides 700% better insulation than bricks and 50% better than glass wool. Its unique cellular structure and trapped gas composition create remarkably low thermal conductivity, requiring minimal thickness for maximum performance.

| Feature | Benefit | Application |

|---|---|---|

| Superior R-value | Uses 3-4cm less thickness | Wall insulation |

| Moisture resistant | Prevents mold growth | Humid spaces |

| Air-tight sealing | Eliminates heat loss | Attic barriers |

| High compression | Maintains structural integrity | Floor insulation |

| Versatile forms | Spray or rigid board options | Custom fitting |

Whether you're insulating walls, roofs, or floors, polyurethane's exceptional thermal efficiency and versatility make it ideal for maintaining consistent temperatures in your Sun Chef setup.

Layered Insulation Techniques

While effective insulation depends on material choice, proper layering techniques ultimately determine your Sun Chef's thermal performance. You'll need to carefully secure insulation blankets using aluminized mylar tape, ensuring 2-inch overlaps at longitudinal seams. By interleaving 5 layers from each edge, you'll markedly reduce heat leaks while maintaining ideal density between layers.

For maximum thermal efficiency, remember these critical installation steps:

- Roll blankets to fit cylindrical vessel portions

- Cut criss-cross patterns to accommodate nozzles

- Position second layers perpendicular to first in double-layer systems

- Use custom patches at support points

When installed correctly, your layered insulation can reflect up to 98% of heat and reduce thermal loads by orders of magnitude. This thorough approach targets radiation, convection, and conduction simultaneously, maximizing your Sun Chef's performance.

Eco-Friendly Material Selection

As environmental consciousness drives innovation in solar cooking, eco-friendly insulation materials offer sustainable alternatives without compromising thermal performance.

You'll find excellent options in natural wool, wood fiber, and cellulose materials that provide superior thermal protection while being biodegradable and recyclable.

These materials don't just insulate – they're multifunctional. Sheep's wool and wood fiber help regulate humidity, while cellulose fiber, made from recycled paper, reduces landfill waste.

You can easily install wood fiber batts between studs, and cellulose can be blown in for uniform coverage.

What's more, these materials are non-toxic and safe for your cooking environment. They're treated for fire resistance and provide bonus benefits like sound insulation.

Frequently Asked Questions

How Long Does Each Insulation Material Typically Last Before Needing Replacement?

You'll find that spray foam and mineral wool last 80-100 years, while fiberglass typically needs replacement after 15-20 years. Cellulose has a moderate lifespan of 20-30 years, though it may degrade earlier.

Can Different Insulation Materials Be Safely Combined in the Same Space?

Yes, you can safely combine different insulation materials in the same space as long as they're compatible. You'll need to guarantee proper surface preparation, maintain fire safety standards, and consider moisture control between layers.

What Are the Best Insulation Options for Extremely Humid Climates?

For extremely humid climates, you'll want to use spray foam or mineral wool insulation. They're highly moisture-resistant and create effective barriers. You can also consider polyester insulation as it naturally resists moisture and mold.

How Do Seasonal Temperature Changes Affect Various Insulation Material Performance?

You'll notice your insulation's performance varies seasonally. In winter, materials like fiberglass and rockwool excel at heat retention, while in summer, reflective materials work best to keep your spaces cool.

Which Insulation Materials Are Most Resistant to Pest Infestations?

You'll find spray foam and polyurethane foam offer superior pest resistance by creating impenetrable barriers. Mineral wool's non-organic composition naturally deters pests, while cellulose treated with boric acid effectively repels common household insects.

In Summary

You've now got the knowledge to choose the perfect insulation for your solar cooking projects. Whether you opt for mineral wool's durability, polystyrene's reflective properties, or eco-friendly cellulose, each material brings unique benefits. Remember to take into account your climate, budget, and environmental impact. By layering materials strategically and focusing on thermal efficiency, you'll maximize your sun chef setup's performance and cooking results.

Leave a Reply