The top 5 container materials for maximizing heat absorption include copper, aluminum, carbon steel, stainless steel, and ceramic. Copper leads with the highest thermal conductivity at 401 W/m·K, making it your best choice for rapid heat transfer. Aluminum follows as a lightweight alternative with excellent 237 W/m·K conductivity. Carbon steel offers reliable 43-60 W/m·K performance, while stainless steel provides 15-25 W/m·K with superior temperature stability. Ceramic materials round out the list with impressive 92.2% solar absorptance and high-temperature resistance. Understanding each material's unique properties will help you make the most efficient choice for your specific needs.

Steel Containers and Heat Conductivity

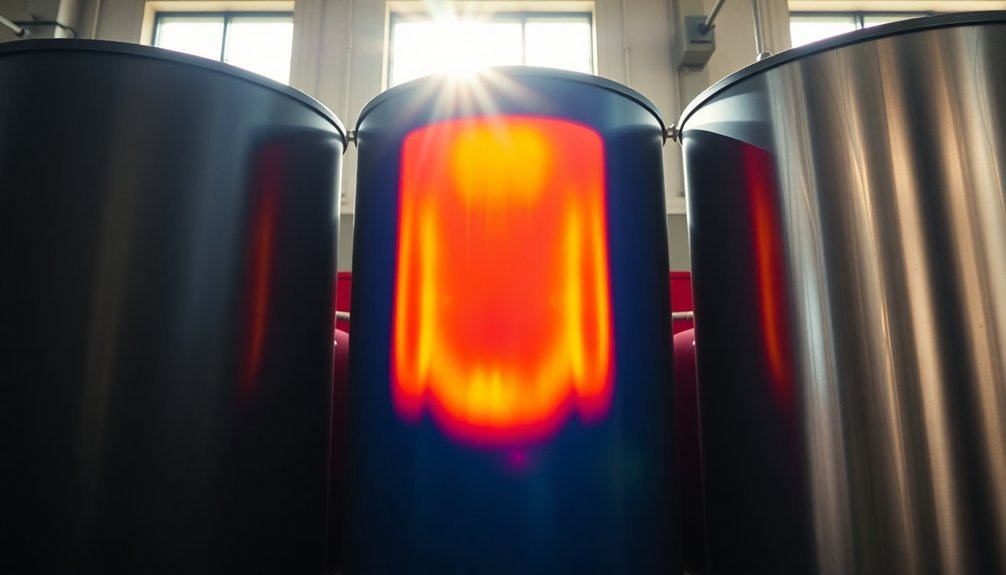

While stainless steel containers are popular for their durability and corrosion resistance, they actually have relatively low thermal conductivity, ranging from 15-25 W/m·K.

You'll find that this thermal conductivity increases with temperature – for example, SS 304 conducts heat at 16.2 W/m·K at 100°C and 21.5 W/m·K at 500°C.

If you're looking for ideal heat transfer, you might want to take into account alternatives.

Carbon steel containers conduct heat much better, with values between 43-60 W/m·K.

However, if you need temperature stability and heat retention, stainless steel's lower conductivity becomes an advantage. The austenitic crystal structure of common grades like 304 and 316 contributes to their lower heat conductivity.

You'll notice this particularly in kitchen appliances and thermal insulation equipment.

Just remember that while stainless steel can withstand temperatures up to 800°C, you shouldn't regularly expose it to temperatures above 300°C to prevent distortion.

Ceramic Materials for Solar Absorption

Moving beyond traditional metal containers, ceramic materials offer remarkable capabilities for solar energy absorption. You'll find that all-ceramic solar selective absorbing coatings (SSACs) achieve impressive solar absorptance of 92.2% while maintaining low thermal emittance of 17.0% at 1,000 K. These coatings are particularly effective due to their shift-metal carbides and nitrides composition.

When you're considering ceramic containers, you'll appreciate that they can withstand temperatures above 1,000°C without significant degradation. They're easily fabricated using methods like magnetron sputtering, and they're enhanced with SiO2 antireflection layers. Research has shown that double-layer coating designs can enhance solar absorptance from 0.625 to 0.944.

The three-dimensional structure guarantees uniform airflow distribution and high permeability, while the high specific surface area maximizes heat exchange. For your heat absorption needs, ceramics provide superior thermal stability and mechanical properties compared to metal alternatives.

Cast Iron Solar Cooking Vessels

Despite its excellent heat retention properties, cast iron presents unique challenges in solar cooking applications.

You'll find that it takes considerably longer to heat up compared to lighter cookware, and its high thermal mass absorbs substantial energy that could otherwise heat your food directly. However, its consistent heat distribution makes it reliable once heated.

While cast iron works well in parabolic cookers where intense heat can quickly raise its temperature, you're better off choosing lighter vessels for most solar cooking needs.

The pot's high mass means more solar energy goes into heating the metal rather than your food. If you're determined to use cast iron, you'll need a full day of strong sunlight and plenty of patience.

For ideal results, consider pairing your cast iron with a steel diffusion plate in parabolic setups.

Aluminum Heat Transfer Properties

Among common metals used for heat absorption, aluminum stands out with its impressive thermal conductivity of 237 W/m·K, enabling rapid and efficient heat transfer through free electron movement. You'll find that pure aluminum offers superior heat conduction compared to its alloys, making it ideal for cookware and heat sinks.

| Property | Value | Application |

|---|---|---|

| Thermal Conductivity | 237 W/m·K | Heat sinks |

| Heat Distribution | Even | Cookware |

| Weight | Light | Electronics |

| Electron Mobility | High | CPU cooling |

| Temperature Range | -40°C to 600°C | Radiators |

When you're selecting aluminum for heat transfer applications, remember that purity matters. While alloying elements can improve strength, they'll reduce thermal conductivity. That's why you'll see pure aluminum in premium heat sinks and cooking vessels where maximum heat transfer is critical.

Copper Container Performance

When considering thermal conductivity in container materials, copper stands out as the superior choice with its remarkable 401 W/mK conductivity rate – nearly twice that of aluminum. You'll find copper's exceptional heat transfer capabilities remain consistent across various temperatures, making it ideal for demanding applications.

While you'll need to factor in copper's higher cost at $6,939 per metric ton and its greater weight at 8940 kg/m³, its durability and 310 MPa tensile strength often justify the investment.

You can rely on copper containers for critical heat management in electronic devices, HVAC systems, and vapor chambers where efficient heat dissipation is essential.

Plus, copper's malleability lets you shape it precisely for your specific container needs, while its recyclability helps offset the initial cost over time.

Frequently Asked Questions

How Do Magnetic Properties Affect Heat Absorption in Container Materials?

You'll find that magnetic properties cause molecules to align with external fields, affecting their thermal energy. When you reduce the field, molecules absorb heat as they randomize their orientations.

Can Container Materials' Heat Absorption Capacity Change With Repeated Thermal Cycling?

Yes, you'll notice your container materials' heat absorption capacity degrades with thermal cycling, as repeated heating and cooling creates microcracks, changes polymer structures, and weakens material integrity, affecting their ability to absorb heat efficiently.

What Role Does Surface Oxidation Play in Long-Term Heat Absorption?

You'll find that surface oxidation typically reduces heat absorption over time, as it creates a barrier layer that interferes with thermal transfer. It can also degrade your material's structural stability and efficiency.

Do Radioactive Materials Enhance or Inhibit Container Heat Absorption Properties?

You'll find that radioactive materials don't enhance heat absorption in containers. They're stored in materials chosen for radiation shielding, not thermal properties. The containers focus on safety rather than heat absorption capabilities.

How Does Altitude Affect the Heat Absorption Efficiency of Different Container Materials?

You'll notice altitude affects heat absorption differently: steel containers lose efficiency in thinner air, while composite materials maintain consistent performance. Higher elevations also reduce convective heat transfer due to lower air density.

In Summary

You'll find that choosing the right container material dramatically affects heat absorption and retention in solar applications. Whether you're using steel, ceramic, cast iron, aluminum, or copper, each offers unique thermal properties for your needs. Consider your specific requirements around conductivity, durability, and cost when selecting materials. Remember that darker surfaces and proper thickness will further enhance your container's heat absorption capabilities.

Leave a Reply