Heat reflects better with mirror methods due to their specialized surface properties and strategic material choices. You'll find that smooth, polished surfaces like silver and aluminum efficiently reflect all components of white light while following the Law of Reflection. These mirror systems can save up to 75% in energy costs compared to ordinary glazing, as they minimize heat loss and gain. When you combine proper mirror placement with advanced materials like heat mirror films, you'll achieve superior temperature control and UV protection. Modern thermal management techniques and sophisticated modeling can help you access even greater efficiency potential.

Understanding Reflection Surface Properties

When light strikes a surface, its interaction largely depends on the surface's physical properties.

You'll find that smoother surfaces, especially those with imperfections smaller than light's wavelength, reflect energy more efficiently.

Mirror-like surfaces, such as polished metals, reflect all components of white light almost equally, making them ideal for heat reflection.

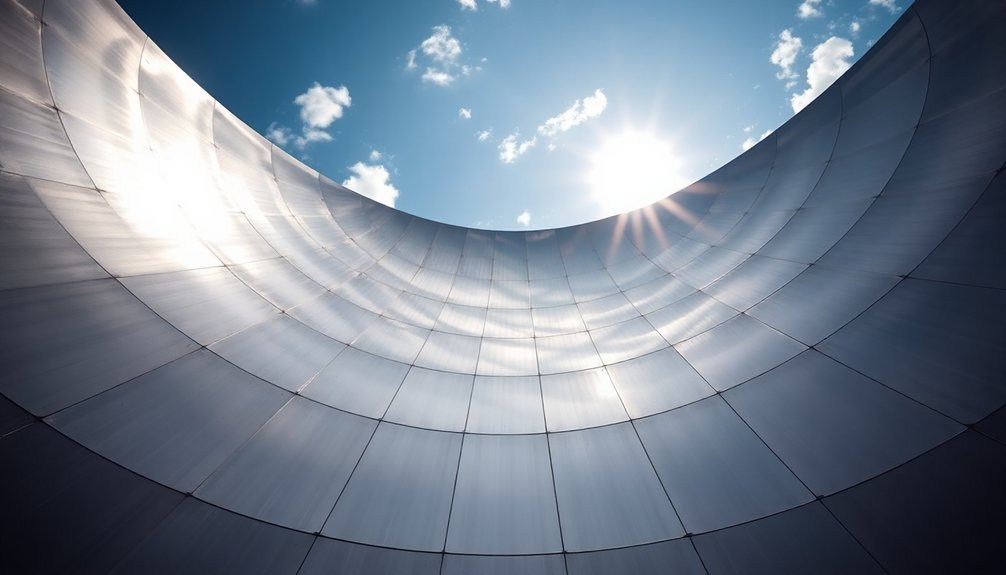

The surface's ability to create specular reflection is vital for effective heat management. Both concave and convex mirrors create distinct reflection patterns that can be utilized for specific heat management applications.

You'll get the best results when the surface maintains the direction and phase of reflected waves, following the Law of Reflection.

This means the angle at which heat hits the surface equals the angle at which it's reflected.

Understanding these properties helps you choose the right materials for heat reflection applications, whether you're working with metallic coatings or specialized reflective surfaces.

Heat Mirror Technology Applications

Thanks to significant advancements in thermal management, heat mirror technology now offers remarkable benefits across residential and commercial buildings.

You'll notice immediate energy savings of up to 75% compared to ordinary glazing, while reducing your carbon footprint.

Originally developed by NASA for space shuttle applications, this innovative technology has proven its effectiveness in both residential and commercial settings.

The technology maintains your room's temperature by minimizing heat loss and gain, keeping interior glass surfaces close to ambient temperature.

You won't have to worry about condensation, as it resists moisture buildup even in high-humidity environments like pool enclosures.

Plus, you'll protect your furniture and decor since it blocks 99.5% of harmful UV radiation.

What's more, you're getting these benefits without the bulk of triple-pane windows – it's 33% lighter while performing better.

The system's superior solar shading and thermal performance make it ideal for maximizing both comfort and energy efficiency in any space.

Material Selection For Maximum Efficiency

Selecting the right materials for heat reflection can dramatically impact your thermal management system's performance.

You'll find silver leads the pack with its superior reflectance and low emissivity, making it ideal for Heat Mirror films. While gold and copper also reflect well, they'll tint your view, so silver's often your best choice.

For maximum efficiency, you'll want to evaluate materials that combine high reflectance with durability. Modern solutions deliver R-10 insulation performance, far exceeding traditional window options.

Aluminum's an excellent option, especially when you need a cost-effective solution.

When you're working with these materials, remember to factor in potential overheating issues – temperatures can exceed 75°C on sunny days.

You can enhance performance by pairing metals with composite materials like fiberglass or Kevlar, which adds structural strength while maintaining reflective properties.

Temperature Control Through Mirror Placement

Beyond material selection, proper mirror placement serves as a powerful tool for temperature regulation in any space.

You'll achieve ideal heat distribution by strategically positioning mirrors to reflect sunlight throughout your room. This technique can slash your heating costs by 15-30% while creating a more balanced indoor climate. Double-framed mirrors provide additional insulation benefits when incorporated into your setup.

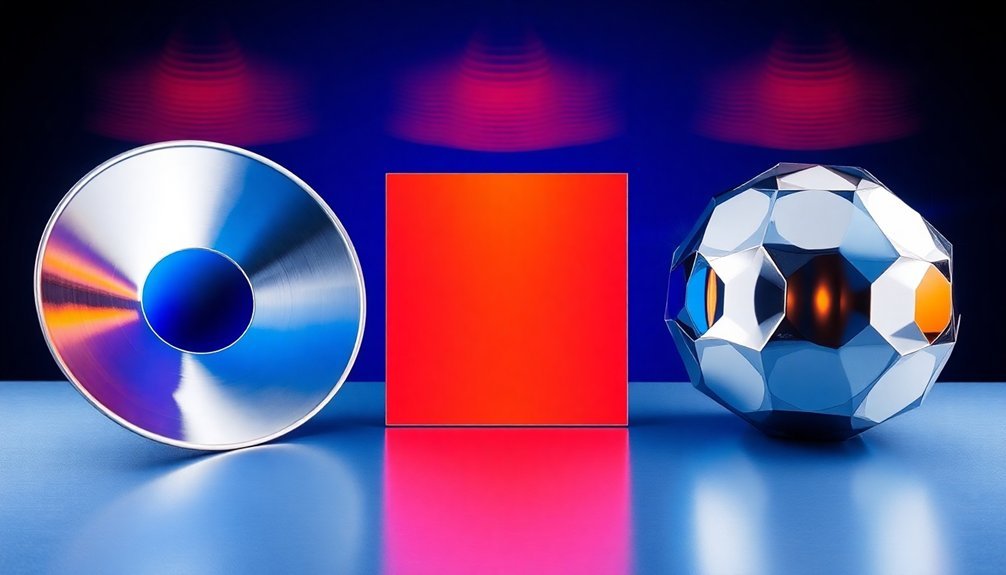

For best results, you'll want to take into account using specialized mirrors based on your specific needs.

Hot mirrors reflect infrared radiation to control heat, while cold mirrors transmit infrared energy while reflecting visible light.

If you're aiming to create concentrated heat zones, try using parabolic mirrors – they'll focus infrared radiation at specific points.

Advanced Heat Distribution Techniques

When implementing advanced heat distribution systems, you'll need to leverage sophisticated computational methods and innovative transfer techniques to achieve ideal thermal management. You'll find that Computational Fluid Dynamics (CFD) and Finite Element Analysis give you precise control over heat flow patterns and thermal behavior.

| Method | Key Benefit |

|---|---|

| CFD Modeling | Quick design iteration testing |

| Thermal Simulation | Hot spot identification |

| Multiphysics Analysis | Interface temperature control |

Your success depends on understanding how micro/nanoscale transfer techniques and compact heat exchangers work together. By applying these advanced methods, you'll enhance baffle configurations and maximize efficiency while keeping material costs low. The combination of empirical correlations and experimental data helps you predict heat transfer rates accurately, ensuring your mirror-based heat distribution system performs at its best under various conditions.

Frequently Asked Questions

How Do Environmental Factors Affect the Longevity of Hot and Cold Mirrors?

You'll find that temperature fluctuations, humidity, radiation exposure, and air pollutants can considerably reduce your mirrors' lifespan. Both hot and cold mirrors need proper maintenance to prevent coating degradation and performance loss.

Can Multiple Hot Mirrors Be Stacked to Enhance Infrared Reflection Performance?

While you can stack hot mirrors, it's not recommended. You'll face reduced visible light transmission, complicated optical paths, and potential interference issues. Single high-quality hot mirrors typically provide better performance than stacked configurations.

What Maintenance Procedures Are Required to Maintain Optimal Mirror Coating Efficiency?

You'll need to regularly dust with nitrogen or clean brushes, avoid touching surfaces, use reagent-grade methanol for contaminants, and keep mirrors dry. Always use fresh tissues and check for coating compatibility before cleaning.

How Do Electromagnetic Interference Patterns Impact Heat Mirror Reflection Capabilities?

You'll find electromagnetic interference patterns create selective wavelength reflection through your mirror's layered coatings. They'll enhance infrared reflection while letting visible light pass, considerably boosting your mirror's heat-reflecting performance.

Are There Specific Humidity Levels That Compromise Heat Mirror Effectiveness?

You'll notice reduced heat mirror effectiveness when indoor humidity exceeds 60%. At this level, condensation forms on the surface, causing the mirror to behave like uncoated glass and lose its thermal benefits.

In Summary

You'll find that mirrored surfaces maximize heat reflection due to their highly polished, low-emissivity properties. By choosing the right materials and positioning them strategically, you're creating an efficient thermal barrier that redirects radiant heat where it's needed. Whether you're managing indoor temperatures or harnessing solar energy, these mirror methods work because they minimize absorption while optimizing reflective capabilities through precise surface engineering.

Leave a Reply