For ideal sun drying, spread your rice in thin 2-4 cm layers and dry between 8 am and 1 pm, when sunlight is most effective. You'll need 6-8 hours of direct sunlight, stirring every 30 minutes to guarantee even drying. Keep your rice off public roads and protected from animals, using clean nylon nets or tarpaulins as drying surfaces. Don't let rice temperature exceed 140°F (60°C) during drying to prevent damage, and cover immediately if rain threatens. Watch for uniform color and firmness as key indicators of readiness, and monitor moisture levels carefully. There's much more to mastering the perfect sun-dried rice technique.

Optimal Sun Drying Duration

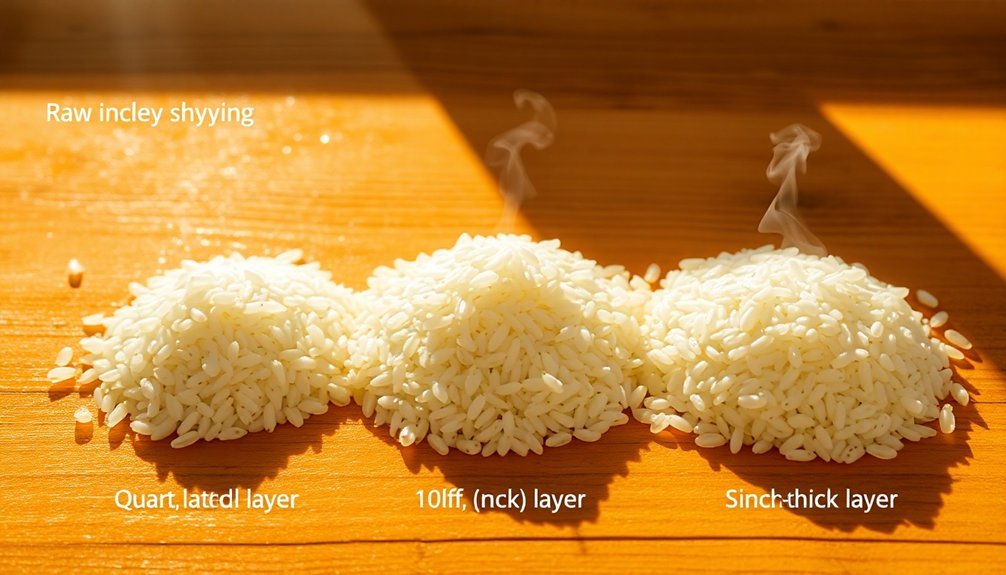

Four key factors determine the ideal duration for sun drying your rice: layer thickness, mixing frequency, environment, and weather conditions.

You'll get the best results by spreading your rice in layers between 2-4 cm thick and stirring every 30 minutes. Don't let layers exceed 5 cm, as this creates uneven drying with wet grains at the bottom.

Choose a well-ventilated area and place your rice on mats or plastic sheets, avoiding public roads or areas where animals can access the grain. Quality maintenance is achieved by keeping the drying area clean and free from debris.

Start drying in the morning hours to prevent overheating, and you'll need to cover your rice immediately if it rains.

For best timing, harvest your rice about 25 days after 75% flowering. By maintaining these conditions, you'll achieve uniform drying while minimizing the risk of cracking and contamination.

Rice Temperature Safety Limits

Three critical temperature ranges determine rice safety: cold storage below 40°F (4°C), the danger zone between 40-140°F (4-60°C), and reheating above 165°F (74°C).

You'll need to refrigerate your cooked rice within 1-2 hours to prevent bacterial growth, or within 1 hour if outdoor temperatures exceed 90°F. Spreading rice in a thin layer in airtight containers helps achieve faster cooling and prevents contamination.

Don't leave your rice in the danger zone, where bacteria like Bacillus cereus can double every 20 minutes.

When you're reheating rice, verify it reaches 165°F throughout by using a food thermometer and stirring for even heat distribution. Add a splash of water to prevent drying.

If you're serving rice without temperature control, you've got a 4-hour window before it must be discarded.

Always mark the discard time on containers and don't reheat rice more than once.

Morning Versus Afternoon Drying

Proper timing makes a significant difference when sun-drying your rice, much like maintaining safe temperatures for cooked rice storage.

You'll get the best results by drying your rice between 8 am and 1 pm, when conditions are ideal for even moisture reduction. Regular moisture monitoring during the drying process helps prevent over-drying and maintains optimal grain quality.

Morning drying yields higher head rice recovery and reduces grain damage compared to afternoon drying. You should spread your rice on nylon nets or tarpaulins in 2-5 cm layers, stirring frequently for uniform drying. If you're not finished after one session, you can continue the next morning.

Avoid drying during afternoon hours, as excessive heat can damage your grains, increase breakage, and cause uneven drying.

While artificial dryers might be more effective, proper morning sun drying remains a viable alternative that'll help preserve your rice quality.

Weather Impact On Drying Time

You'll need at least 6-8 hours of direct sunlight for effective sun drying of your rice, but cloudy conditions can extend this timeframe considerably.

If rain occurs during the drying process, you must immediately cover or collect your rice to prevent moisture absorption and potential fungal growth. The model suggests maintaining a drying capacity of 4.37m³/h for optimal results.

High humidity levels will lengthen your drying time, while consistent wind flow can help speed up the process by enhancing moisture removal.

Daily Sunlight Hours Needed

While sun-drying rice might seem straightforward, the timing and duration of sunlight exposure play crucial roles in achieving ideal results.

You'll want to focus on morning hours when the sun isn't too intense, avoiding the harsh midday heat that can damage your grains.

- Plan your drying sessions during consistent sunlight periods, typically in the morning hours

- Adjust your drying time based on your location's seasonal sunlight patterns

- Monitor local weather forecasts to pick best drying days

- Limit exposure during peak heat hours to prevent grain cracking

Remember that effective drying doesn't mean leaving your rice out all day. Instead, you'll need to work with nature's rhythm, considering both the intensity and duration of sunlight.

Your location's specific climate patterns will ultimately determine the most effective drying schedule.

Rain Delay Factors

When rain clouds gather overhead, your rice drying schedule can quickly become derailed. High humidity and rainfall can stall drying fronts, keeping your harvest at elevated moisture levels for weeks. You'll face significant challenges if you're in an area with two rainy seasons per year.

Your biggest concerns during rain delays are moisture content (MC) and temperature. When MC stays between 19-21% and temperatures hover at 20-40°C, you're risking both reduced head rice yield and unwanted fungal growth.

The relative humidity of the surrounding air will dramatically slow your drying rate, creating ideal conditions for kernel discoloration. To protect your harvest, you'll need to aim for prime storage conditions of 10-15°C with MC between 12.5-19%.

Consider using alternative drying methods if prolonged rain threatens your sun-drying process.

Layer Thickness Guidelines

For successful rice cooking, proper layer thickness plays a crucial role in achieving perfectly cooked grains.

You'll need to guarantee your rice forms at least a 1/2-inch layer on the bottom of your pan while keeping the raw rice volume to no more than one-fourth of the container.

When preparing your rice, follow these essential guidelines:

- Choose a pan that's 3 times larger than your raw rice volume

- Use a heavy-duty stainless steel or nonstick pan with a tight-fitting lid

- Confirm water completely covers your rice layer

- Shake the pan gently to create an even rice distribution

Remember that different rice types expand differently, so you'll need to adjust your ratios accordingly.

For instance, jasmine rice requires more water than other varieties to achieve the perfect layer thickness.

Stirring Schedule And Techniques

Regular stirring of sun-drying rice every 30 minutes is essential to maintain uniform moisture content and prevent quality issues.

You'll need to guarantee thorough mixing to avoid moisture gradients that can lead to cracked grains.

While traditional methods like rakes work well, you can use mechanical stirrers or hand-propelled units to make the process more efficient.

During stirring, create channels to help rainwater runoff and arrange the rice in rows that you can easily cover when needed.

Don't let the grain temperature exceed 50-60ºC on hot days.

Keep your stirring area clean and protected from animals.

You'll want to cover the rice immediately if it starts raining or during mid-day heat.

Be gentle while stirring to avoid damaging the grains, and make certain you're not introducing contaminants like stones or dirt during the process.

Moisture Testing Methods

Accurate moisture testing guarantees your rice reaches the ideal dryness level for storage and processing.

You'll find several reliable methods to measure moisture content, each with distinct advantages for different situations.

- The oven method serves as the gold standard – while it takes 16 hours at 130°C, it'll give you the most accurate results.

- If you're looking for quick results, an infrared moisture balance can analyze your sample in just 6.5 minutes after grinding.

- Electronic meters offer practical field testing – choose between resistance-type for small samples or capacitive for higher accuracy.

- For non-destructive testing, you can opt for SWIR or FT-NIR spectroscopy, which lets you measure bulk samples without damaging the rice.

Select the method that best fits your needs, considering factors like time constraints, sample size, and required accuracy level.

Storage Readiness Indicators

You'll know your rice is ready for storage by testing its moisture content using reliable methods like grain hardness checks or moisture meters.

Look for firm, uniform grains that break cleanly rather than mashing when pressed between your fingers.

Before storing, confirm there's no softness or stickiness in the grains, as these physical signs indicate the rice needs more drying time.

Moisture Content Testing Methods

Testing rice's moisture content properly is essential for determining storage readiness and preventing costly losses.

You'll find several reliable methods to measure moisture levels, each with its unique advantages.

For accurate results, you can use these proven testing approaches:

- The traditional oven method offers high precision by drying samples at 105°C for about 2 hours, comparing weights before and after drying.

- Infrared moisture balances provide quick results within minutes using small 2-gram samples, with impressive accuracy and automated controls.

- Portable moisture meters, both resistance and capacitive types, work well for field testing during harvest.

- Electronic meters need proper calibration but give instant readings perfect for on-site decisions.

Choose the method that best fits your needs, considering factors like time constraints, required accuracy, and testing location.

Physical Signs of Readiness

When storing rice for extended periods, recognizing physical signs of readiness becomes essential for maintaining quality and preventing spoilage.

You'll want to check for a uniform color without dark spots or discoloration, as these can indicate contamination. The grains should feel firm, not soft or sticky, and maintain their individual integrity.

Pay attention to any unusual odors – properly stored rice should have a neutral smell. If you notice foul odors or see any signs of mold, insects, or chalky kernels, the rice isn't suitable for storage.

A quick sensory check of cooked rice can also reveal quality issues. Remember that rice hardness increases during storage, especially at higher temperatures, so you'll need to store it in airtight containers to protect against moisture and pests.

Grain Hardness Assessment

Reliable grain hardness assessment serves as a vital indicator of rice storage readiness.

You'll want to check the grain's physical resistance and texture, as these properties directly affect storage stability and milling quality.

Temperature and moisture conditions during storage greatly influence rice grain hardness through changes in lipid metabolism.

To properly assess rice grain hardness, you can use these proven methods:

- NIR reflectance testing for quick, non-destructive hardness measurements

- Compression testing to evaluate the grain's mechanical properties

- Particle size index (PSI) testing to determine texture characteristics

- Visual inspection of grain vitreousness as a supplementary indicator

Remember that proper storage conditions are essential – maintaining appropriate temperature and moisture levels will help preserve ideal grain hardness throughout the storage period.

Frequently Asked Questions

Can Rice Be Sun-Dried on Cloudy Days With Indirect Sunlight?

You can sun-dry rice on cloudy days, but it's not recommended. You'll face considerably longer drying times, higher risks of fungal growth, and reduced grain quality. Consider using mechanical drying methods instead.

How Does Altitude Affect the Sun-Drying Time for Rice?

While altitude itself won't considerably affect solar radiation, you'll notice slower drying times at higher elevations due to cooler temperatures. You'll need to account for thinner air and more extreme temperature fluctuations.

What Color Changes Indicate Properly Sun-Dried Rice?

You'll know your rice is properly sun-dried when it maintains its natural whitish color. Don't let it turn yellow or brown. Well-dried grains should appear uniform and bright, not dull or discolored.

Does Rice Variety Affect the Required Sun-Drying Duration?

Yes, you'll find that rice varieties greatly affect drying times. For example, Pka Knhey takes about 15.5 hours to dry, while CAR11 needs around 14 hours. These differences can vary by up to 1.5 hours.

Can Previously Sun-Dried Rice Be Dried Again if Accidentally Rewetted?

Yes, you can dry rewetted rice again, but you'll need to spread it thinly (2-4 cm) and mix frequently. Be extra careful to prevent cracking and guarantee even drying by monitoring temperature closely.

In Summary

You've learned the key elements of successfully sun-drying rice, from timing your drying sessions to monitoring temperature and moisture levels. Remember to spread your rice in thin, even layers, stir regularly, and check for proper dryness before storage. By following these temperature guidelines and drying techniques, you'll protect your harvest from spoilage while preserving its quality. You're now equipped to dry rice effectively and safely.

Leave a Reply