Curved panels transfer heat more effectively than flat surfaces because they maximize surface area for heat exchange, achieving over 700 m²/m³ density. You'll find they create complex 3D flow patterns and vortices that enhance fluid mixing and reduce boundary layer thickness, leading to 22% better heat transfer compared to straight panels. They're particularly effective in solar applications, where curved reflectors can concentrate sunlight up to 500 times more than flat panels. When combined with ideal materials like copper or aluminum, and strategic design features like finned passages, curved panels considerably boost thermal efficiency. Discovering the intricate physics behind curved panel design reveals even more impressive capabilities.

Basic Principles of Curved Surfaces

In the domain of engineering and physics, curved surfaces represent continuous, smooth geometries that deviate from flat planes. You'll find these surfaces defined by equations relating coordinates x, y, z, often expressed as W = 0, where W is a function of these coordinates.

When you're working with curved surfaces, you'll need to understand two key elements: tangents and normals. Tangents touch the surface at a single point without intersecting it, while normals stand perpendicular to these tangents. This design principle is particularly effective at reducing visual distortion when applied to modern display technologies.

You can classify curved surfaces as either regular or irregular. Regular surfaces follow predictable patterns, like spheres and cylinders, while irregular surfaces exhibit more complex, chaotic structures.

In engineering applications, you'll typically encounter regular surfaces, which are easier to model using CAD techniques like B-Splines and NURBS.

Surface Area and Heat Exchange

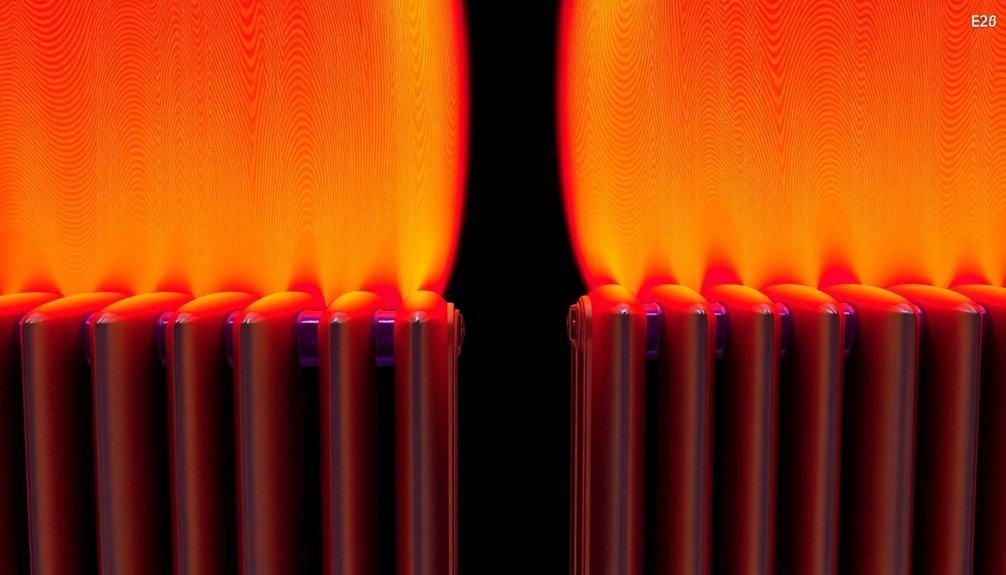

Curved surfaces in engineering take on special significance when you consider their role in heat transfer applications. When you're designing heat exchangers, curved panels give you a major advantage by maximizing the surface area available for heat transfer while keeping the overall volume compact. You'll find these designs can exceed 700 m²/m³ in surface area density. The heat transfer mechanisms through these curved surfaces include conduction, convection, and radiation, working together to maximize thermal efficiency.

| Design Feature | Benefit | Application |

|---|---|---|

| Curved Panels | Increased Surface Area | Electronics Cooling |

| Finned Passages | Enhanced Fluid Mixing | Heat Exchangers |

| Optimized Geometry | Space Efficiency | Compact Systems |

The enhanced surface area isn't just about quantity – it's about quality too. Curved panels improve heat transfer by promoting better fluid mixing and reducing boundary layer thickness. You'll get more effective heat dissipation, especially in applications where space is at a premium, like cooling electronic components.

Fluid Flow Over Curved Panels

When fluid flows over curved panels, it creates complex three-dimensional patterns due to secondary flows and vortices.

You'll notice large streamwise vortices forming along the inner wall, which greatly affect how the fluid moves and transfers heat. The velocity profiles aren't static – they continuously change along the curved section, shifting from symmetric patterns to profiles with peaks near either the inner or outer walls.

These flow patterns increase the pressure drop and friction coefficients, especially along the outer wall where they're about 50% higher than in straight channels. Just like how curved monitors require an optimal viewing distance of 73cm, the fluid flow patterns require specific distances for maximum effectiveness.

While this might seem disadvantageous, it actually helps with heat transfer. When both walls are heated, you'll get about 22% better heat transfer than with straight panels, thanks to the enhanced mixing and turbulence from these secondary flows and vortices.

Heat Distribution Patterns

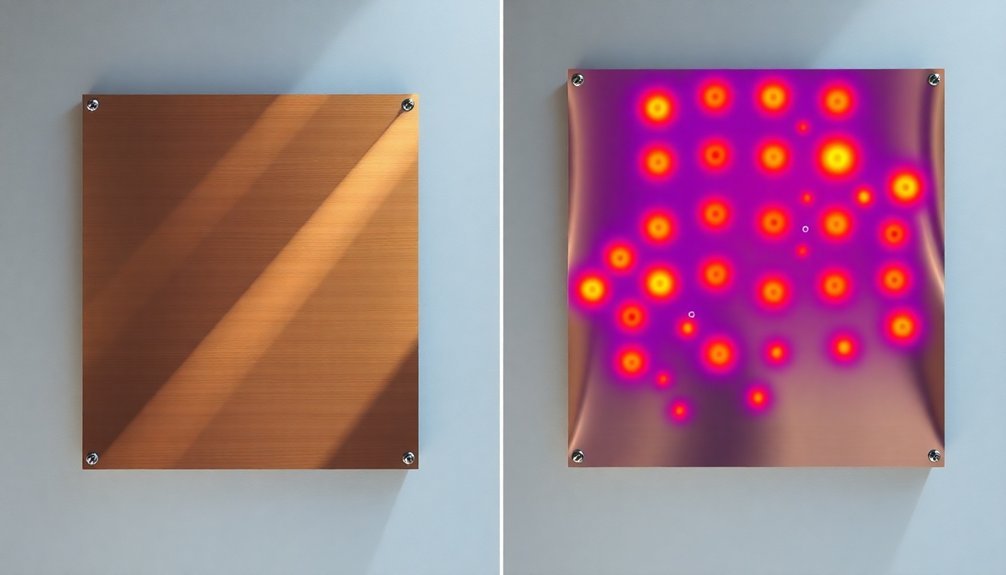

Understanding heat distribution patterns requires careful consideration of the curvature parameter ξ and its relationship with heat generation.

You'll find that curved surfaces greatly alter how heat disperses, particularly when the radius of the boundary layer decreases.

When you're working with curved panels, you'll notice that Joule heat generation concentrates under the coil, following its shape. As curvature increases, there's a notable reduction in heat generation near the symmetry axis – up to 21% at high curvature values. This effect becomes more pronounced when you're dealing with coil widths exceeding 100 mm.

The finite element method provides detailed analysis of electromagnetic, thermal, and mechanical aspects of heat distribution in curved panels.

You'll see enhanced heat transfer efficiency through curved thermal boundary layers, which can deliver considerably higher heat flux compared to flat surfaces.

The Nusselt number scale (Nu ∼ξ−1/5Ra1/4) indicates that smaller ξ values result in larger heat flux.

Material Selection for Curved Panels

When you're selecting materials for curved panels, you'll need to take into account both thermal conductivity and curvability, with copper and aluminum offering superior heat transfer compared to steel options.

You'll find that surface treatments like anodizing or powder coating can affect both the heat transfer properties and the material's ability to maintain its curved form during thermal cycling.

The manufacturing process you choose, whether it's mechanical curving or crimp curving, will impact the panel's thermal performance by altering the material's surface area and contact points for heat distribution.

Thermal Conductivity Comparisons

Since thermal conductivity plays a significant role in curved panel design, comparing different materials' heat transfer capabilities becomes essential for peak performance. You'll find that copper stands out with its impressive 355 W/m°K conductivity, making it ideal for demanding thermal applications. While aluminum offers a cost-effective alternative at 175 W/m°K, it's still highly efficient for most curved panel needs.

| Material | Thermal Conductivity (W/m°K) | Cost Factor | Formability |

|---|---|---|---|

| Copper | 355 | High | Excellent |

| Aluminum | 175 | Moderate | Good |

| Graphite | Variable | High | Limited |

| FR4 | 0.25 | Low | Good |

When you're selecting materials, remember that directional conductivity matters too. Graphite, for instance, conducts heat differently along its planes, while copper maintains consistent performance in all directions.

Surface Treatment Options

Surface treatments dramatically enhance curved panels' thermal performance beyond their base material properties.

You'll find that techniques like sol-gel, cladding, and electroplating can greatly improve heat transfer capabilities while protecting against corrosion and wear.

For ideal thermal conductivity, you can choose from several advanced coating methods.

PVD techniques, particularly magnetron sputtering, allow you to create precise thin films that enhance heat transfer. If you're working with nickel-base alloys, plasma and thermal spraying are especially effective.

Even a minimal gold coating can boost heat pipe performance by 300 times.

You'll want to take into account ion implantation when you need both improved thermal properties and reduced friction.

This technique, using ions like N+, B+, and C+, creates a durable surface that maintains its enhanced characteristics over time.

Manufacturing Process Impact

The selection of materials for curved panels directly impacts your manufacturing process and thermal performance outcomes.

You'll find that copper and aluminum are prime choices, with copper offering superior thermal conductivity but requiring careful handling due to its electrical properties.

For more flexible applications, you can opt for graphite sheets that provide excellent heat dissipation along their layer planes while being lighter than aluminum.

Your manufacturing approach needs to take into account ultra-fine precision processing at 10 microns to create effective heat dissipation components.

When you're working with curved surfaces, vapor chambers with fine flow channels and capillary structures offer ideal performance in confined spaces.

You'll need to contemplate how secondary currents and vortices affect heat transfer rates, as outer-wall heat transfer can be 40% more efficient than straight channels.

Design Optimization Strategies

Optimizing curved panels for heat transfer requires careful consideration of multiple interrelated design parameters.

You'll find that the jet-to-surface distance is essential – keeping it lower typically yields higher heat transfer rates by reducing boundary layer thickness.

When you're designing your system, you'll want to focus on optimizing jet angles and velocities, as these considerably impact heat transfer uniformity and effectiveness.

Don't overlook the importance of surface velocity and curvature interactions.

You'll need to carefully balance these elements, as lower relative surface velocities can improve heat transfer by minimizing boundary layer disruption.

For multiple jet configurations, you'll want to optimize the spacing between jets to prevent interference.

Using CFD simulations with appropriate turbulence models like SST k-ω will help you validate your design choices and predict performance accurately.

Solar Energy Concentration Effects

When harnessing solar energy through curved panels, concentration effects play a crucial role in maximizing power output and thermal efficiency.

You'll find that curved reflectors outperform traditional flat panels by redirecting sunlight more effectively at various sun angles, increasing the effective panel length and energy capture.

- Concentration systems can achieve factors of 50+ suns for linear focus and 500+ suns for point focus collectors

- Heat generation can reach temperatures over 1,000°C using particle-based systems, enabling efficient energy storage

- Real-world systems operate at 25-60% below theoretical maximums, but curved configurations help minimize these losses

Through advanced curved designs, you're able to capture more sunlight throughout the day and convert it into usable heat for steam turbines or thermochemical reactions, making solar energy more practical and dispatchable.

Temperature Control Through Panel Design

Through careful attention to component placement and airflow design, effective temperature control in curved panels requires strategic planning from the ground up. You'll find that placing power supplies at the top and PLCs at the bottom creates natural heat dissipation paths, while strategic fan placement enhances airflow efficiency.

| Design Element | Benefit | Implementation |

|---|---|---|

| Vertical Spacing | Natural heat rise | Mount hot components high |

| Component Separation | Reduced interference | Use physical barriers |

| Airflow Pattern | Enhanced cooling | Bottom intake, top exhaust |

For ideal results, you'll want to implement 3D modeling to visualize heat patterns and component placement before construction. This approach lets you identify potential hot spots and adjust your design accordingly. When possible, opt for passive cooling methods over fans to increase reliability and reduce maintenance needs.

Real World Performance Results

Based on extensive testing and validation, curved fin designs consistently outperform traditional flat configurations in real-world applications.

Both numerical simulations and experimental data confirm that curved panels with grooves achieve superior heat transfer rates compared to conventional designs. You'll find these improvements are particularly noticeable in applications like engine cylinders, where efficient heat dissipation is essential.

- Elliptical fins with grooves show up to 25% better heat transfer performance than circular or flat fins

- Advanced software tools like ANSYS and CATIA V5 help engineers optimize curved panel designs for maximum efficiency

- The combination of increased surface area and enhanced fluid flow around curved surfaces creates ideal conditions for heat dissipation

These real-world results demonstrate why curved panels are becoming the preferred choice in thermal management applications, where every degree of improvement matters.

Frequently Asked Questions

How Do Curved Panels Perform in Extreme Weather Conditions Like Snow or Hail?

You'll find curved panels perform exceptionally well in extreme weather. They resist hail impacts with Class 4 rating, while their design effectively manages snow loads and accommodates various snow retention solutions like adhesive-mounted guards.

Can Curved Panels Be Effectively Cleaned Without Damaging Their Heat Transfer Properties?

Yes, you can safely clean curved panels using gentle mechanical methods and appropriate cleaning solutions. Focus on soft brushes, avoid abrasives, and protect thermal interface materials to maintain ideal heat transfer properties.

What Is the Average Lifespan of Curved Heat Transfer Panels?

You'll typically get 15-20 years from curved heat transfer panels if you maintain them properly. However, your panel's lifespan can vary considerably based on material quality, operating conditions, and maintenance practices.

How Do Manufacturing Defects Impact the Efficiency of Curved Heat Panels?

Manufacturing defects can greatly harm your curved panel's efficiency through uneven thickness, surface contamination, and poor geometry. You'll notice reduced heat transfer rates and potential hot spots where materials aren't properly formed.

Are Curved Panels More Susceptible to Thermal Fatigue Than Flat Panels?

Yes, you'll find curved panels are generally more susceptible to thermal fatigue than flat ones due to their complex stress distributions, residual manufacturing stresses, and the additional bending stresses created by their curved geometry.

In Summary

You've learned how curved panels maximize heat transfer through increased surface area, optimized fluid dynamics, and enhanced thermal distribution. They'll give you better performance than flat panels in most applications, especially when you're working with solar concentration or temperature-sensitive processes. By selecting appropriate materials and implementing smart design principles, you'll achieve more efficient heat exchange and improved temperature control in your thermal systems.

Leave a Reply