For heat-absorbing bakeware, you'll find ceramic and cast iron are top performers with natural non-stick properties. Ceramic offers excellent heat distribution and chemical-free cooking, while well-seasoned cast iron provides superior thermal mass and heat retention. Both materials work exceptionally well in solar applications, with ceramic ensuring even cooking and cast iron maintaining consistent temperatures. You can also consider porcelain with dark coatings, which efficiently absorbs visible light and maintains food flavors. For easy maintenance, choose FDA-approved ceramic or properly seasoned cast iron. There's much more to discover about these sustainable cooking solutions.

Understanding Solar Heat Absorption Properties

Solar heat absorption plays a critical role in how materials respond to thermal energy. When choosing bakeware materials, you'll want to understand how different surfaces interact with heat.

Dark-colored, matte surfaces absorb more heat than light, shiny ones – making them ideal for achieving even baking results. Some advanced materials can now be engineered to achieve near-perfect absorption of heat energy.

The material's specific heat capacity and thermal conductivity determine how efficiently it'll absorb and distribute heat throughout your baked goods. High thermal conductivity metals will transfer heat more effectively than materials with lower conductivity.

You'll also need to take into account the material's density and volumetric specific heat, as these properties affect how much heat energy it can store. For best baking performance, look for materials that combine good heat absorption with efficient heat distribution properties.

Selecting Natural Non-Stick Materials

While traditional non-stick coatings have raised health concerns, several natural materials offer excellent food-release properties without synthetic chemicals.

You'll find ceramic bakeware particularly effective, as it's made from natural minerals that create an inherent non-stick surface. It's safe at high temperatures and won't release harmful VOCs. Today's FDA-approved materials ensure optimal food safety when choosing ceramic options.

If you're looking for durability, opt for ceramic-coated options with a metal core.

Glass bakeware provides another chemical-free alternative that's easy to clean and maintains consistent heat distribution.

For flexibility, consider silicone bakeware, which offers natural non-stick properties without PFAS or PTFE.

Stainless steel stands out as a practical choice, though it works best when properly seasoned. Just be mindful that it may interact slightly with acidic or salty foods.

Cast Iron Solar Performance

While cast iron's thermal mass allows it to absorb and hold onto solar energy longer than most cookware, you'll need to be patient as it heats up gradually in sunlight.

The high density and strength of cast iron makes it exceptionally effective at maintaining consistent temperatures once fully heated.

You can improve your cast iron's solar performance by maintaining a well-seasoned surface that efficiently captures and distributes heat from the sun.

Your investment in cast iron's thermal properties will pay off through superior heat retention and even cooking temperatures, especially when using a parabolic solar cooker.

Heat Absorption Superiority Explained

Although cast iron is renowned for its heat retention capabilities, its performance in solar cooking applications reveals some surprising characteristics.

You'll find that cast iron's thermal conductivity (27-46 BTU/hr-ft-F) is considerably lower than aluminum or copper, which impacts its heat absorption rate in solar applications.

When you're using cast iron in a solar oven, you'll notice it takes longer to heat up initially compared to thinner, darker materials. The material's high melting point of 2,150-2,360°F contributes to its slower initial heating response.

However, once your cast iron reaches its target temperature, you'll benefit from its exceptional heat retention properties.

This trade-off means you'll need to plan for longer cooking times, but you won't have to worry about temperature fluctuations once your food starts cooking.

For ideal solar cooking results, you might want to take into account preheating your cast iron cookware before use.

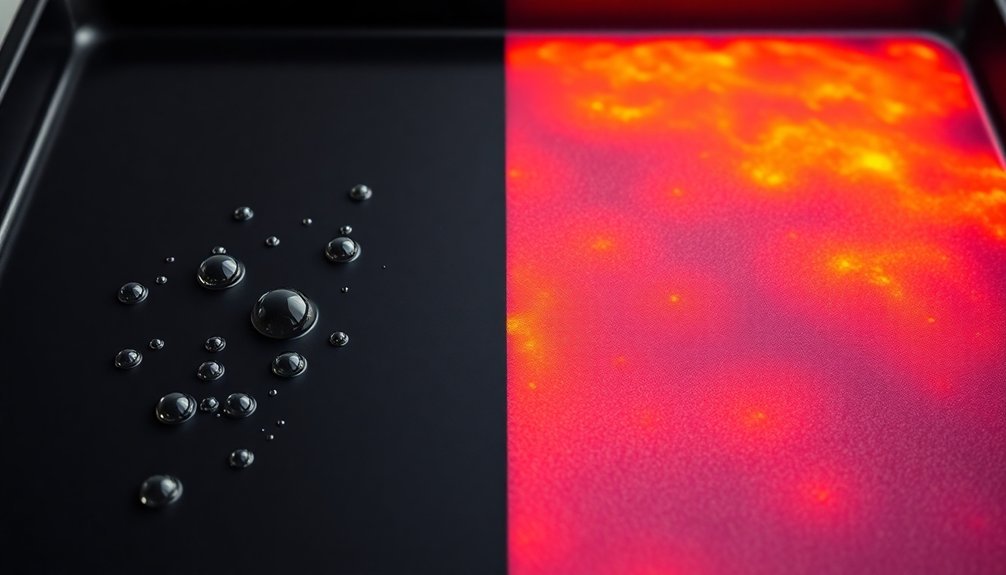

Surface Seasoning For Sunlight

Once exposed to sunlight, a properly seasoned cast iron surface impacts its solar cooking performance markedly. You'll find that polymerized oil molecules create a dark, semi-glossy finish that enhances heat absorption. While you can use Sunlight liquid for cleaning, it's best to avoid it as it may strip your carefully built seasoning layer.

| Seasoning Factor | Solar Impact | Maintenance Needs |

|---|---|---|

| Dark Surface | High absorption | Regular oiling |

| Glassy Layer | Heat retention | Gentle cleaning |

| Oil Bonds | Even heating | Re-season if stripped |

To maintain peak solar cooking performance, you'll want to use polyunsaturated oils like grapeseed or sunflower for seasoning. After each use, apply a thin oil layer and avoid rich fats. The surface will continue improving with proper care, enhancing your pan's solar cooking capabilities through its non-stick, heat-absorbing properties.

Thermal Mass Benefits Revealed

Building on the seasoning's role in solar cooking, let's explore cast iron's remarkable thermal mass properties. You'll find that cast iron's density allows it to store more heat energy than most other cookware materials, making it excellent for maintaining steady temperatures during long cooking sessions.

While cast iron isn't the fastest conductor compared to aluminum or copper, its high thermal mass means you won't need to adjust your heat settings as frequently.

When using cast iron in solar cooking, you'll need to account for longer heating times, especially on partially cloudy days. For ideal results, you'll want to use parabolic solar cookers, which can generate enough heat to overcome cast iron's slow initial heating.

Despite this limitation, once your cast iron reaches the desired temperature, it'll maintain consistent heat throughout your cooking process.

Ceramic Heat Distribution Benefits

When it comes to baking success, ceramic's exceptional heat distribution capabilities stand out among non-stick materials.

You'll notice that your baked goods cook uniformly throughout, eliminating frustrating hot spots that can lead to uneven results. You won't need to constantly rotate your pans or worry about burnt edges and raw centers.

The ceramic's natural ability to spread heat evenly means your dishes will cook at a consistent rate, preserving the natural flavors of your ingredients. For best results, remember to preheat your ceramic bakeware properly and stick to medium heat settings.

To maintain these benefits, you'll want to avoid metal utensils and high temperatures that could damage the coating.

Regular cleaning with gentle soap and a soft sponge will keep your ceramic bakeware performing at its best for years to come.

Porcelain Solar Baking Applications

Taking solar baking to the next level, porcelain-coated bakeware offers remarkable advantages for eco-conscious cooking enthusiasts.

You'll find that dark porcelain coating absorbs visible light efficiently while retaining heat, making it ideal for solar ovens that can reach temperatures from 65°C to 400°C.

For best results, choose round roasters with tight-fitting lids to prevent heat escape. You'll need proper insulation and reflectors to maximize heat retention and concentrate sunlight.

The non-reactive surface won't affect your food's flavor, and you'll appreciate how easy it's to clean.

While solar cooking takes longer than conventional methods, you can cook various dishes from stews to desserts.

Just remember that you'll need sunny weather and hot pads for handling, as the porcelain surfaces become extremely hot during use.

Modern Silicone Solar Solutions

Silicone bakeware revolutionizes solar cooking with its impressive temperature tolerance and non-stick properties. You'll find this versatile material perfect for solar ovens, as it can withstand temperatures from freezing to 428°F while maintaining its structural integrity. Unlike traditional materials, high-quality silicone won't leach chemicals into your food during the solar cooking process.

| Feature | Benefit |

|---|---|

| Heat Range | -40°F to 428°F safe usage |

| Durability | Maintains shape, won't crack |

| Safety | Food-grade, chemical-free |

| Maintenance | Dishwasher safe, easy clean |

| Storage | Flexible, space-saving design |

The eco-friendly nature of silicone makes it an ideal choice for sustainable solar cooking. You can transfer dishes directly from cold storage to your solar oven without worrying about thermal shock, and the non-stick surface guarantees easy food release and cleanup.

Glass Bakeware Solar Efficiency

Glass bakeware offers unique thermal properties that distinguish it from silicone in solar cooking applications. You'll notice it heats up more slowly than metal alternatives but retains heat longer, which can be both an advantage and challenge for solar cooking.

While glass isn't the most efficient heat conductor, it's excellent at trapping solar energy through its transparent surface.

If you're using glass bakeware in a solar oven, you'll want to contemplate using double-glazed sheets spaced about 40mm apart to maximize the greenhouse effect. You can achieve temperatures above 100°C, making it suitable for boiling and cooking.

Though you'll need proper insulation to prevent heat loss, glass bakeware's durability and low maintenance make it a practical choice, especially when using borosilicate glass that can withstand temperature differences up to 330°F.

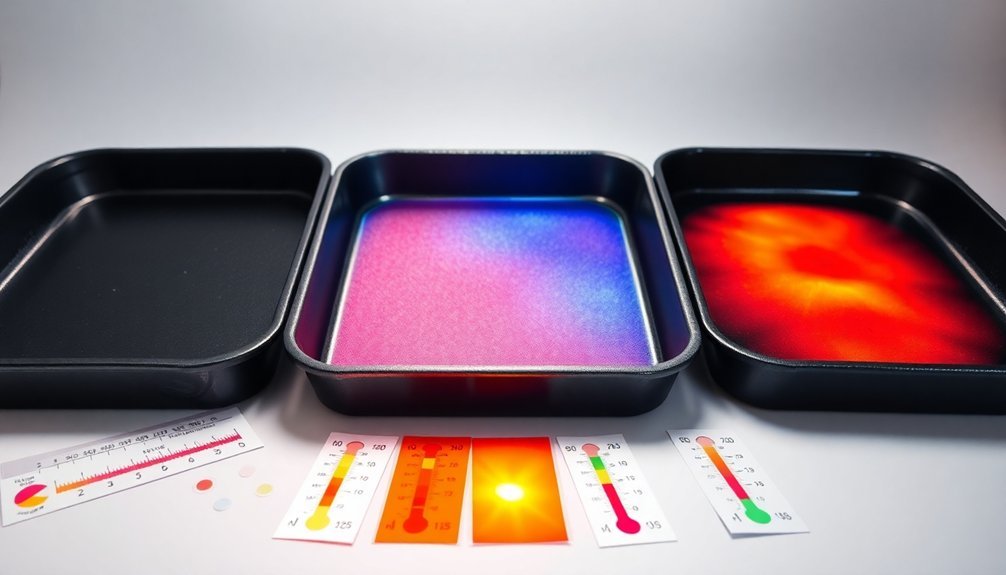

Material Heat Retention Comparisons

Understanding how different bakeware materials retain heat can dramatically impact your baking results.

Cast iron stands out as the champion of heat retention, keeping your dishes warm long after they've left the oven.

While ceramic offers similar benefits with even heat distribution, it's more delicate and requires careful handling.

Stainless steel and aluminum present contrasting properties – aluminum heats quickly but cools rapidly, while stainless steel takes longer to heat but maintains temperature steadily.

- Cast iron's exceptional heat retention makes it ideal for dishes requiring consistent temperature maintenance

- Ceramic's balanced heat distribution works best for gentle, even baking tasks

- Aluminum's quick heating and cooling properties suit recipes needing precise temperature control

- Stainless steel's moderate heat retention offers a middle-ground option for versatile baking needs

Maintenance For Solar Bakeware

To maintain your solar bakeware's heat-absorbing surfaces, you'll want to clean them regularly with a mild, biodegradable soap solution and a soft sponge, similar to how you'd care for solar panels.

Your bakeware's nonstick layer requires gentle handling, so avoid abrasive cleaners and metal utensils that could scratch or damage the coating.

When storing your solar bakeware, place soft cloth or paper towels between stacked pieces to protect the specialized surfaces and prevent unnecessary wear on the nonstick coating.

Preserving Heat-Absorbing Surfaces

Maintaining your solar bakeware's heat-absorbing surfaces requires careful attention to four key practices.

You'll need to use mild detergents and soft cleaning materials while avoiding harsh chemicals or abrasive tools that could damage the surface. After cleaning, thoroughly dry the surfaces to prevent water spots and mineral buildup that can reduce efficiency.

- Clean immediately after each use with gentle cleaners and soft cloths to prevent stubborn residue accumulation.

- Monitor surface temperatures during use, avoiding extreme heat that could compromise the coating.

- Inspect regularly for signs of wear, particularly focusing on areas that show discoloration or decreased performance.

- Store in a dry environment, avoiding stacking to prevent scratches and maintaining proper air circulation between uses.

Nonstick Layer Protection Tips

While solar bakeware offers excellent cooking performance, proper care of its nonstick layer guarantees lasting durability and ideal results.

You'll need to clean your bakeware gently with mild soap and warm water, using only soft sponges or cloths. Never use abrasive cleaners or metal scrubbers that can damage the coating.

Keep your cooking temperature at medium heat and monitor it carefully to prevent harmful fumes. You should also stick to silicone, nylon, or wooden utensils when cooking, as metal tools can scratch the surface.

Don't forget to maintain the coating by occasionally seasoning it with a light oil coating, if your manufacturer recommends it.

When storing your bakeware, avoid stacking pieces to prevent scratches, and inspect the surface regularly for signs of wear.

Surface Treatment Options

Before any non-stick coating can be applied effectively, proper surface preparation forms the foundation for durable bakeware.

You'll need to verify the carbon steel surface is thoroughly cleaned and free from oils, grease, and other impurities. Surface roughening may be necessary to improve coating adhesion before applying primers and final coatings.

- Choose ceramic primers for superior bonding between the metal surface and your non-stick coating.

- Apply PTFE, ceramic, or silicone coatings in multiple thin layers for maximum coverage.

- Consider PPG HALO coating systems for enhanced durability and even heat distribution.

- Monitor curing temperatures carefully – ceramic coatings require up to 2,000°C for proper hardening.

The final treatment process involves quality inspections and potential aesthetic enhancements, verifying your bakeware's non-stick surface meets performance standards while maintaining visual appeal.

Testing Different Materials

To guarantee safety and longevity in non-stick bakeware, manufacturers conduct extensive material testing through standardized procedures.

You'll find these tests focus on two main areas: durability and chemical safety.

For durability, they'll check the coating's abrasion resistance by repeatedly scrubbing the surface, measure impact resistance through drop tests, evaluate hardness using pencil tests, and assess adhesion by grid-scoring the surface.

You can trust that your bakeware has been rigorously tested to withstand daily use.

Chemical safety testing is equally thorough.

Manufacturers follow strict standards like EN 12983-1 and FDA 21 CFR 175.300 to ascertain there's no harmful metal release or chemical reactions.

They'll expose the coating to acids, oils, and detergents to verify it maintains its integrity under real kitchen conditions.

Frequently Asked Questions

Can Stainless Steel Bakeware Be Used in Direct Sunlight Without Warping?

You won't need to worry about sunlight warping your stainless steel bakeware. While it's durable against environmental conditions, you should still avoid sudden temperature changes and excessive heat for best results.

How Does Humidity Affect Different Bakeware Materials During Solar Cooking?

When you're solar cooking, humidity affects your bakeware differently: aluminum can resist moisture well, cast iron may rust without proper care, and stainless steel won't corrode but might have reduced heat efficiency in humid conditions.

Which Material Is Safest for Children Helping With Solar Baking?

You'll find ceramic bakeware is safest for children helping with solar baking. It's non-toxic, chemical-free, and easy to handle. Plus, its natural materials won't leach harmful substances when exposed to heat.

Do Dark-Colored Materials Perform Significantly Better Than Light-Colored Ones?

Yes, dark-colored materials perform noticeably better for solar baking. You'll find they absorb heat faster and more efficiently than light colors, which reflect more heat away. This means quicker cooking times.

What's the Average Lifespan Difference Between Traditional and Solar-Specific Bakeware?

You'll find traditional bakeware typically lasts 10-20 years longer than solar-specific types. While traditional pieces can last decades with proper care, solar-specific bakeware often needs replacement every 5-7 years due to coating degradation.

In Summary

You'll find that different non-stick materials offer unique benefits for solar baking. Cast iron and ceramic remain top choices due to their excellent heat absorption and retention. For best results, maintain your solar bakeware with proper seasoning and cleaning techniques. Test various materials to discover what works best in your climate and cooking conditions. Remember to take into account both heat performance and non-stick properties when making your selection.

Leave a Reply